Multiflex Expansion Joint Filler

Multiflex expansion joint filler is an essential component in the construction industry, especially for civil engineering projects that require high durability and resistance to various types of movement.

The multiflex expansion joint filler is designed to withstand displacement, rotational, horizontal, or vertical movement. RK Rubber Philippines offers two types of multiflex expansion joint fillers, the single module and bridge module, custom-molded from high-grade rubber materials.

The functionality of the multiflex expansion joint filler plays a crucial role in ensuring the longevity and stability of civil engineering structures such as national highways, airports, and bridges.

The need for reliable products in the construction industry has made RK Rubber Philippines a go-to supplier for many construction companies throughout the country.

In this article, we will delve deeper into the features and applications of multiflex expansion joint filler while highlighting its durability and resistance capabilities.

Overview

This section provides an overview of the multiflex expansion joint filler, a product that acts as a bridge between two separate structures.

Its primary function is to withstand various movements such as displacement, rotational, horizontal, or vertical movement that can occur due to external factors.

It offers riding comfort to travelers while reducing stress on the structure.

The installation process for this product is crucial and must be done correctly.

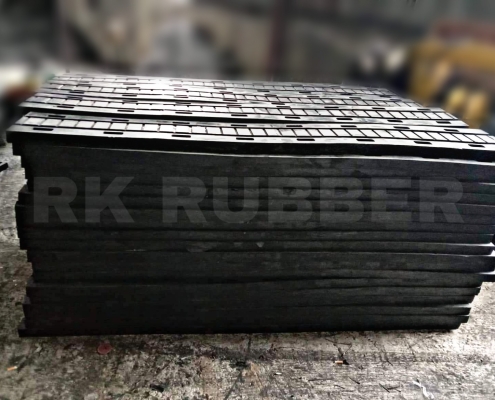

The multiflex expansion joint filler comes in two types: single module and bridge module.

These are custom-molded from high-grade rubber materials depending on project requirements.

As it is mainly used in civil engineering sectors for building national highways, airports, bridges, and other superstructures, cost analysis should be considered before implementation.

The cost analysis of using multiflex expansion joint fillers involves evaluating its durability and reliability compared to alternative products available in the market.

This process includes assessing its resistance to weather conditions like extreme temperatures or corrosion/chemical exposure over time.

A well-thought-out cost analysis will help determine whether using this product is feasible for specific projects or not.

Different Applications

The multifunctional nature of the expansion joint filler has led to its widespread application in civil engineering, particularly in the construction of national highways, airports, bridges, and other large-scale infrastructures that require flexibility in accommodating various types of structural movement.

Expansion joint fillers are critical components for these structures as they can withstand displacement, rotational, horizontal, or vertical movement. They serve as a bridge between two separate structures while providing riding comfort to travelers and reducing stress on the structure due to their excellent vibration resistance.

One significant benefit of using expansion joint fillers is their ability to prevent damage caused by thermal expansion and contraction. This type of structural movement can cause cracks and fissures in concrete slabs if not adequately addressed. Expansion joints allow for controlled movements without affecting the surrounding structures’ integrity.

Additionally, these materials have high tear and wear resistance properties making them ideal for high-traffic areas such as national highways. The use of expansion joint fillers also ensures a longer lifespan for infrastructure projects by minimizing maintenance costs associated with structural damages caused by uncontrolled movements.

Moreover, they enhance safety measures by preventing accidents resulting from uneven surfaces due to uncontrolled structural movements. As such, modern-day civil engineering projects prioritize the inclusion of expansion joint fillers to ensure maximum longevity and safety while maintaining aesthetic appeal within infrastructure projects.

Features

The features of the aforementioned material include its capacity to endure extreme weather conditions, excellent resistance to corrosion and chemicals, exceptional shear resistance, and a non-skid surface made possible by high-grade elastomer.

With these features, multiflex expansion joint filler is suited for civil engineering purposes such as building national highways, airports, bridges, and other superstructures. The installation process may vary depending on the project or client’s needs, but it is essential to ensure that the materials used are of high quality.

Maintenance tips for multiflex expansion joint filler include regular cleaning to remove dirt and debris that may accumulate over time. It is also crucial to inspect the material regularly to detect any signs of wear or damage early on. Immediate repair or replacement should be done if necessary to avoid further damage or potential hazards.

Proper maintenance ensures that the material retains its durability and reliability even after years of use. Multiflex expansion joint filler’s exceptional qualities make it an ideal material for construction projects requiring structures capable of withstanding various movements such as rotational, horizontal, and vertical structure movements.

The use of high-grade elastomer ensures that it can withstand harsh weather conditions while maintaining a non-skid surface that provides safety for travelers. Its reliability in providing long-lasting performance makes it an excellent investment option for construction companies looking for durable materials for their projects.

Durability

The durability of the material is a crucial aspect to consider when selecting construction materials, as it ensures the longevity and safety of the structures built.

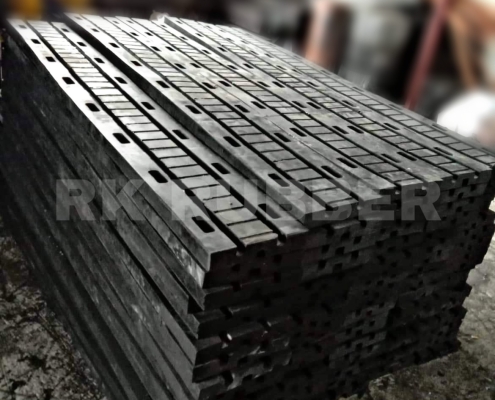

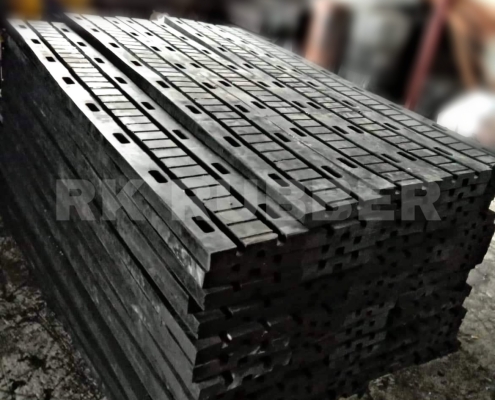

The multiflex expansion joint filler offered by RK Rubber Philippines is known for its long-lasting durability. It consists of high-grade elastomer surrounding a metal sheet that can withstand various types of movement, including vertical and horizontal movements.

To ensure the longevity and reliability of this material, proper installation procedures should be followed. This includes ensuring that all necessary preparations are made before installation, such as cleaning and drying the area where the filler will be placed.

Maintenance tips such as regular inspection and cleaning should also be implemented to prevent any damage or deterioration over time.

Overall, choosing durable construction materials such as multiflex expansion joint fillers is essential in building long-lasting structures that prioritize safety and quality. With proper installation procedures and maintenance practices, these materials can provide excellent resistance against extreme weather conditions while maintaining optimal performance for years.

Resistance

Resistance is a critical characteristic when selecting construction materials, as it allows structures to withstand external factors such as extreme weather conditions and chemical corrosion.

With the multiflex expansion joint filler, resistance is one of its main features. The high-grade elastomer surrounding this product’s metal sheet provides excellent tear and wear resistance, making it ultra-durable and reliable in extreme weather conditions.

Apart from its durability, this joint filler also has excellent corrosion or chemical resistance. This feature makes it ideal for civil engineering projects such as national highways, airports, bridges, and other superstructures.

The multiflex expansion joint filler’s exceptional shear resistance further enhances its ability to resist various rotational, horizontal, and vertical structure movements.

To ensure that our customers receive only top-quality products from us, we subject our multiflex expansion joint fillers to rigorous testing and certification processes. We ensure they meet industry standards before we release them into the market. By doing so, clients can have peace of mind knowing they are getting durable and reliable products that meet their specific needs.

Compound Materials

The manufacturing process and material selection play a significant role in producing high-quality multiflex expansion joint fillers.

To ensure the durability and reliability of our products, RK Rubber Philippines uses only high-grade elastomer materials in combination with metal sheets during manufacturing.

Our multiflex expansion joint filler is composed of EPDM, natural rubber, or synthetic rubber materials.

These compounds provide excellent tear and wear resistance, making them suitable for heavy-duty construction and civil engineering applications.

The metal sheet adds strength and stability, providing a non-skid surface with exceptional shear resistance.

Moreover, these compound materials offer excellent corrosion and chemical resistance properties that can withstand extreme weather conditions.

This feature makes our multiflex expansion joint filler ideal for building national highways, airports, bridges, and other superstructures where exposure to harsh environmental elements is inevitable.

At RK Rubber Philippines, we guarantee that our multiflex expansion joint fillers are ultra-durable and can handle various movements such as vertical and horizontal movements of a structure.

Conclusion

Multiflex expansion joint fillers are essential in constructing national highways, airports, and bridges. These fillers can withstand various types of movement, including displacement, rotational, horizontal or vertical movement.

RK Rubber Philippines offers two types of multiflex expansion joint fillers custom-molded from high-grade rubber materials: the single module and the bridge module. The company guarantees its products’ durability, reliability and quality.

The different applications for these fillers make them a vital part of any construction project. They provide a solution to accommodate movement between structures while preventing damage or structural failure caused by forces such as weathering or seismic activity.

Thanks to their resistance, these fillers can withstand extreme conditions such as high temperatures or chemical exposure.

In conclusion, multiflex expansion joint filler is an essential part of civil engineering projects requiring infrastructure flexibility and durability. These components offer a reliable solution for accommodating movement between structures while minimizing damage caused by external factors.

With its ability to resist harsh environmental conditions and its long-lasting durability, it is no wonder why many construction companies trust RK Rubber Philippines as their go-to supplier for these crucial components.