Preformed Expansion Join Filler

Preformed expansion joint filler is a popular term in civil engineering. It is a tool used or placed between two concrete, such as highways and sideways, to prevent road damage caused by extreme weather changes and other external factors. It is natural for highways or roads to have horizontal or vertical movement, but it has limits. The placement of preformed expansion joint filler between them is necessary to ensure that there will be no cracks in the concrete due to the ever-changing climate/temperature that is likely to cause accidents to motorists.

Concrete is not elastic, so it cannot be bent or stretched. It is possible to have a catastrophic(or earthquake), especially on national highways. Therefore, our local governments require contractors and builders to install expansion joint filler in any government projects they will make to extend its durability and lifespan.

Characteristics of preformed expansion joint filler

Compound materials options for joint filler

Preformed expansion joint filler is vital to many construction projects and provides the flexibility needed for structures to move with natural temperature changes. Consequently, a suitable material must be chosen for each application, as incorrect selection can result in a loss of performance or even more severe problems.

Two common materials used for this purpose are ethylene propylene diene monomer (EPDM) rubber and foam. Both types offer distinct advantages depending on their use. EPDM rubber provides excellent resistance to weathering, UV radiation, and ozone making it ideal for outdoor applications. Foam expanders have strong abrasion resistance and acoustic insulation properties making them suitable for indoor uses such as air ducts or between floor joists.

Shape and size options for expansion joint filler

The construction and maintenance of roads, highways, and byways is a complex and ever-changing field of work. To ensure roads can withstand the strain of heavy traffic, preformed expansion joint filler can fill any gaps between the concrete slabs that make up these roads. This form of filler comes in various shapes and sizes to accommodate all types of road projects.

One shape commonly used for expansion joint filler is an angular form that allows it to fit tightly against the angle created by two concrete slabs when they meet at an angle. This form ensures no gaps along this angled edge that could expand due to ground movement or other forces. Other common forms include circular, rectangular, and square shapes with dimensions ranging from small enough for residential sidewalk gap filling to large sufficient for bridges or highways.

Applications of Preformed Expansion Joint Filler

- Railways

- Bridges

- Buildings

- Ports or Piers

- Street sidewalks

- Piping procedures

- Concrete Slabs

- Service Roads / Highways

- and other superstructure

Preformed expansion joint filler is essential to construction and repair projects for commercial, industrial, and rail applications. The filler forms a flexible sealant between the two parts of a structure, allowing it to expand or contract without damaging the integrity of the building. It is often used in bridge and highway construction, railway tracks, airports, factories, and other large structures.

Various materials can form preformed expansion joint fillers, including rubber, metal, or plastic composites. The choice of material depends on the application; rubber fillers are usually suited for smaller joints, while larger ones may require a combination of metal composite fillers with additional foam padding providing greater flexibility. These fillers give freedom from movement and protection from water seepage, dust particles, and insects entering through structural gaps.

Installation of preformed expansion joint filler

Tools and equipment for installation

Several tools and equipment must be used when installing preformed expansion joint filler. Before beginning the installation process, it is important to have all the necessary items for a successful outcome. For example, a power saw or manual hacksaw can cut the filler to size before installation. In addition, safety goggles and heavy-duty gloves should always be worn during cutting. Once cut, an adhesive can be applied with an applicator gun or brush to affix the filler firmly.

Finally, a roller tool is generally used after installation to ensure that any air bubbles have been released from underneath the material and that it has successfully adhered to its surrounding surface area.

With these tools before beginning work, any contractor can feel confident installing preformed expansion joint filler quickly and safely.

Step-by-step instructions for installation

Preformed expansion joint filler installation could appear difficult at first, but with the appropriate guidance, it can be simple.

- The first step is to prepare the area where the filler will be laid thoroughly. This includes cleaning out any dirt or debris from the area, removing any existing sealant or caulk, and ensuring that any cracks are evened out. After properly preparing the area, cut your expansion joint filler to size using a sharp knife or an electric saw.

- Once you have done this, apply a primer coat to help bond the filler to its surface and let it dry for at least 30 minutes.

- Finally, use a caulking gun to apply adhesive along both sides of the expansion joint before placing your pre-cut piece of filler into position – make sure all sides are securely sealed.

Features

- It absorbs contraction and expansion, especially in an earthquake scenario.

- Extremely durable and can handle high loads.

- High resistance against any extreme weather condition

- Resistance to chemicals, corrosion, gas, fluids, and ozone.

- Excellent tear and wear resistance

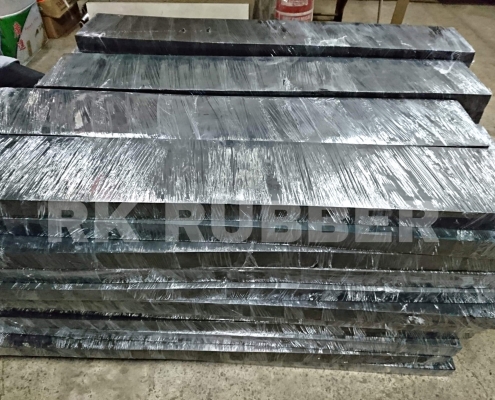

RK Rubber Philippines uses the best compound rubber materials to produce a durable and reliable joint filler. Please be advised that the products’ dimensions may vary depending on the specifications provided by the clients. Kindly contact our sales team for more details about the performed expansion joint filler and other customized rubber-related products.

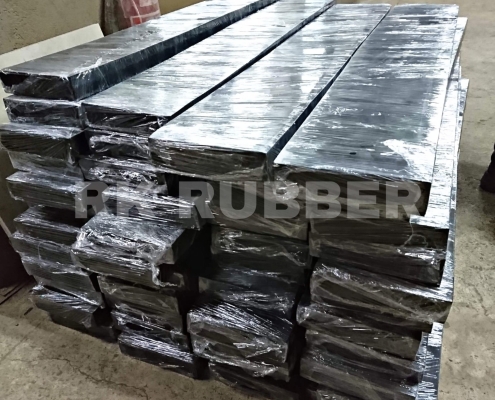

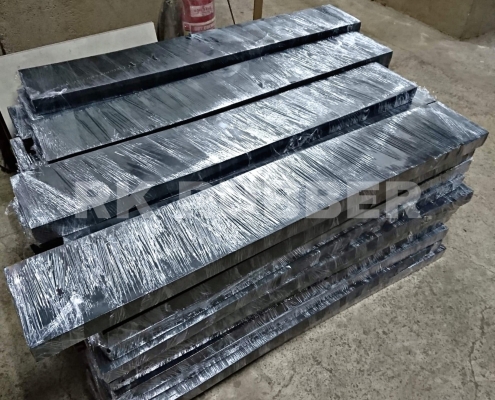

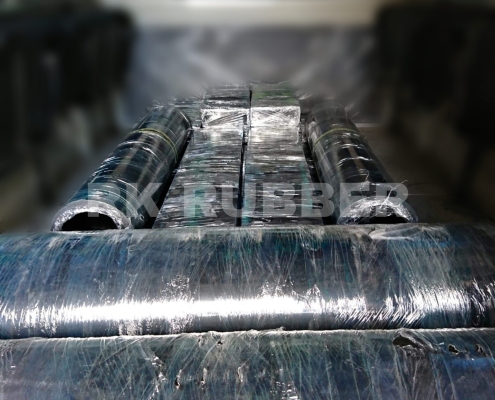

Below are some of the actual products and applications.