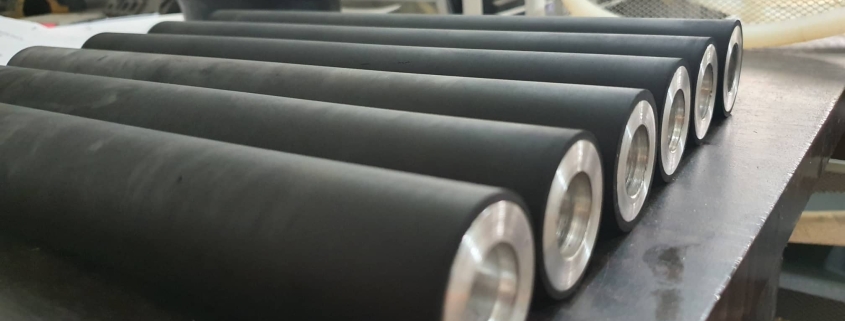

Rubber Rollers

Rubber Rollers Manufacturer in the Philippines | RK Rubber Enterprise Co.

RK Rubber Enterprise Co. is a renowned rubber rollers manufacturer in the Philippines, specializing in custom solutions for various industries. The company produces a range of industrial rollers, including laminator, feed, printing, conveyor, and heat transfer rollers, utilizing diverse rubber compounds and additives to guarantee peak performance. By customizing dimensions, textures, colors, and materials, RK Rubber Enterprise Co. caters to specific client needs, enhancing properties such as adhesion, heat resistance, and anti-static features. With expertise in manufacturing and quality control, RK Rubber Enterprise Co. delivers high-quality products that contribute to industries’ efficiency and competitiveness, and discovering more about their innovations reveals the possibilities that await.

Key Points

- RK Rubber Enterprise Co. is a reputable rubber rollers manufacturer in the Philippines, offering custom solutions for diverse industries.

- The company specializes in producing high-quality laminator, feed, printing, conveyor, and heat transfer rollers for various applications.

- RK Rubber Enterprise Co. utilizes a range of rubber compounds and additives to enhance durability and performance in its products.

- The manufacturer adheres to industry-specific regulations and compliance standards, ensuring its rubber rollers meet necessary specifications.

- RK Rubber Enterprise Co. focuses on customer satisfaction, service excellence, and innovation in its manufacturing process to provide tailored solutions.

Types of Industrial Rollers

Several types of industrial rollers cater to diverse applications, each serving a specific purpose in various manufacturing processes. The primary function of these rollers is to facilitate material movement, processing, or finishing. Laminator rollers, for instance, play a vital role in the lamination process, applying pressure and heat to bond materials together. Feed rollers, on the other hand, are used to transport materials, ensuring smooth and consistent movement.

Printing rollers are another type of industrial roller, specifically designed for the printing industry. These rollers apply ink or other coatings to materials, such as paper or fabric. In addition to these, there are also conveyor rollers, heat transfer rollers, and embossing rollers, each serving a unique purpose in various industrial settings.

The design and construction of these rollers vary depending on their intended application. Material selection, surface texture, and dimensions are critical factors in determining the performance and efficiency of industrial rollers. Understanding the different types of industrial rollers and their applications is essential for selecting the right roller for a specific manufacturing process.

Rubber Roller Materials

The choice of materials used in the construction of rubber rollers is essential in determining their performance, durability, and overall efficiency in various industrial applications, as it directly impacts their ability to withstand the rigors of manufacturing processes. Several key factors influence material selection, including the type of application, operating conditions, and desired lifespan of the roller.

Rubber compounds are the primary material used in the construction of rubber rollers. These compounds typically consist of natural or synthetic rubber blended with various fillers, such as carbon black, to enhance their durability and resistance to wear. Other additives, including plasticizers and anti-aging agents, can also be incorporated to improve the material’s properties. The specific formulation of the rubber compound will depend on the intended application, with different formulations optimized for properties such as hardness, flexibility, and resistance to chemicals or heat.

Custom Design Capabilities

RK Rubber Enterprise Co.’s expertise in rubber compound formulation and manufacturing enables the company to offer custom design capabilities for clients seeking tailored rubber roller solutions. This capability allows clients to specify exact dimensions, textures, colors, and materials to suit their unique applications. By tailoring the design of the rubber roller to the specific needs of the client, RK Rubber Enterprise Co. guarantees peak performance and efficiency in various manufacturing processes.

The company’s custom design capabilities cater to diverse industrial requirements, including mechanical, packaging, printing, and food processing. By understanding the specific needs of each industry, RK Rubber Enterprise Co. can develop customized rubber roller solutions that meet the exacting standards of each sector. The company’s expertise in rubber compound formulation enables it to create rollers with specific properties, such as strong adhesion, heat resistance, and anti-static properties. This level of customization guarantees that clients receive rubber rollers that are precisely suited to their needs, resulting in improved efficiency and productivity. By offering custom design capabilities, RK Rubber Enterprise Co. sets itself apart as a leading manufacturer of rubber rollers in the Philippines.

Manufacturing and Quality Control

Manufacturing high-quality rubber rollers is a complex process that demands meticulous attention to detail and stringent quality control measures. At RK Rubber Enterprise Co., we employ a rigorous manufacturing process that begins with rubber compounding, where we mix synthetic rubber with fillers such as carbon black to enhance durability. The mixture is then poured into molds and cured to achieve the desired form and strength. Our rollers undergo machining and polishing to guarantee they have the correct size and a smooth finish.

Material inspection is a critical step in our quality control process, where we check for defects, cracks, or imperfections. Our quality control measures confirm that our rollers can withstand intense compression stress and maintain a consistent surface quality for peak rolling performance. We also adhere to industry-specific expertise and compliance standards to assure that our products meet the required specifications. By combining expertise, precision engineering, and rigorous testing, we deliver high-quality rubber rollers that meet the specific needs of our clients. Our commitment to quality and precision sets us apart as a leading manufacturer of rubber rollers in the Philippines.

Applications and Uses

Several industries rely on high-quality rubber rollers to maintain efficient and effective manufacturing processes. From mechanical and material handling to packaging and printing, these versatile rollers play a critical role in various sectors. In the printing industry, for instance, rubber rollers are used in offset printing, flexography, and gravure printing to transfer ink and maintain consistent surface quality. In packaging, they facilitate the conveyance and wrapping of products, while lamination guarantees smooth bonding of materials.

In food processing, rubber rollers are used in applications such as dough processing, fruit and vegetable sorting, and meat handling. They are also employed in paper and plastic processing, where they facilitate the cutting, folding, and conveying of materials. Additionally, rubber rollers are used in textile manufacturing, where they aid in the dyeing, printing, and finishing of fabrics. The customization options available for rubber rollers enable manufacturers to tailor their products to specific industrial requirements, guaranteeing peak performance and efficiency in various applications.

Maintenance and Repair Tips

Proper maintenance is essential to extending the lifespan of rubber rollers and guaranteeing their best performance, as neglect can lead to premature wear, reduced efficiency, and increased maintenance costs.

To maintain peak performance and extend the lifespan of rubber rollers, the following practices are recommended:

- Cleaning: Clean rollers with mild soap and water to remove dirt, debris, and chemicals that can damage the rubber. Avoid using harsh chemicals or abrasive materials that can cause wear.

- Storage: Store rollers in a cool, dry place away from direct sunlight and extreme temperatures. This will prevent degradation of the rubber material and reduce the risk of damage.

- Inspection: Regularly inspect rollers for signs of wear, cracks, or damage. Identify and address any issues promptly to prevent further damage and guarantee peak performance.

Benefits of Customized Rollers

Effective rubber roller maintenance practices can greatly prolong the lifespan of these critical industrial components. However, customization of rubber rollers can offer numerous benefits in addition to effective maintenance. Customized rollers are tailored to meet specific industrial requirements, ensuring peak performance and efficiency in various manufacturing processes.

| Customization Aspect | Benefits | Industrial Applications |

|---|---|---|

| Dimensional specificity | Improved product quality, reduced material waste | Lamination, packaging, printing |

| Texture and surface finish | Enhanced product handling, reduced product damage | Food processing, mechanical handling |

| Material selection and compounding | Increased durability, resistance to chemicals and heat | Chemical processing, pharmaceuticals |

Frequently Asked Questions

What Certifications Does RK Rubber Enterprise Co. Hold?

Certifications held by RK Rubber Enterprise Co. are not explicitly stated, however, their commitment to rigorous testing processes, use of premium materials, and adherence to industry standards imply potential compliance with ISO 9001 and other relevant quality certifications.

Can RK Rubber Enterprise Co. Provide OEM Services?

RK Rubber Enterprise Co. offers Original Equipment Manufacturer (OEM) services, providing customized rubber roller solutions tailored to clients’ specific requirements, leveraging expertise in precision engineering and material science to meet diverse industrial needs.

What Is the Typical Lead Time for Custom Orders?

The typical lead time for custom orders is contingent upon complexity, material sourcing, and production schedules. Standard custom orders usually take 4-6 weeks, while complex designs or high-volume orders may require 8-12 weeks for completion.

Does RK Rubber Enterprise Co. Offer Free Product Samples?

Upon inquiry, RK Rubber Enterprise Co. typically provides product samples for new customers and custom orders, enabling them to assess product quality and performance before bulk procurement, subject to certain conditions and minimum order quantities.

Are RK Rubber Enterprise Co.’S Products Export-Compliant?

RK Rubber Enterprise Co.’s products adhere to international export standards, ensuring compliance with regulations and industry-specific requirements, thereby facilitating seamless global trade and distribution of their customized rubber rollers to diverse markets worldwide.

Conclusion

The production of high-quality rubber rollers is essential in driving operational efficiency and effectiveness across various Philippine industries. RK Rubber Enterprise Co.’s all-encompassing approach to manufacturing, quality control, and customization enables the delivery of durable and reliable rubber rollers. This strategic combination of precision engineering and tailored solutions fosters a competitive edge, solidifying the company’s position as a trusted partner for businesses requiring specialized rubber rollers.