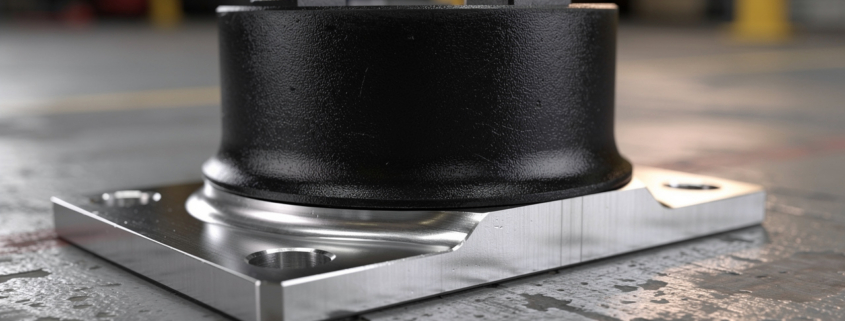

Rubber to Metal Bonding for Durable Industrial Mounts

Every quiet CNC machine and every stable chiller on a rooftop is standing on something most people never notice. Between the steel base and the concrete, soft rubber mounts absorb vibration and shock. When those mounts rely on strong rubber to metal bonding, equipment runs smoother, lasts longer, and stays safer for everyone around it.

Getting that bond right is much harder than it looks. The rubber has to cling to the metal while the mount flexes thousands of times, sometimes in high heat, near oil or chemicals, or under heavy impact. One wrong adhesive choice, or a shortcut in surface preparation, can lead to peeling, cracked rubber, or sudden failure that shuts down production.

There is no single best way to join rubber and metal. Different elastomers, such as natural rubber, neoprene, silicone, or butyl, behave differently on steel, aluminum, or cast iron. Load, temperature range, vibration level, and chemicals on site all change how we design the mount and which bonding system we choose.

At RK Rubber Enterprise Co., we focus on metal-bonded elastomer mounts and other vibration control products for Philippine industries, serving sectors within the growing Rubber-To-Metal Bonded Articles Market that spans automotive, industrial machinery, and infrastructure applications. We combine material science, adhesive know-how, and process control to design mounts that keep machinery stable in factories, automotive plants, commercial buildings, and infrastructure projects. Our work follows strict ISO 9001 quality systems and uses test methods based on ASTM and DIN standards, so each mount performs the way it was specified.

In this guide, we share how we think about rubber to metal bonding for custom industrial mounts. We will walk through bonding basics, how we choose the right adhesive, the way surface preparation affects actual performance in the field, and the checks that keep bonds reliable. By the end, it becomes much easier to speak with our engineering team, ask the right questions, and specify mounts that match real operating conditions.

As many maintenance managers like to say, “Vibration mounts rarely fail in the catalog; they fail on the plant floor.”

Key Takeaways

- Substrate compatibility sits at the base. Rubber and metal must match well. Wrong pairs weaken any bond quickly over time.

- Neoprene adhesives resist oils and chemicals. They also cope well with wide temperatures. This keeps mounts steady in harsh plants.

- Surface preparation is never optional. Clean, roughened metal helps the adhesive grip. Good prep often doubles bond life.

- Custom engineering of rubber and metal matters. We tune hardness, thickness, and geometry. That gives mounts better damping and load sharing.

- Quality checks protect against hidden issues. We monitor bond-line thickness and surface finish. Consistent inspection supports long service in the field.

Understanding Rubber-To-Metal Bonding Fundamentals

Rubber to metal bonding is part chemistry and part surface engineering. On a clean, prepared metal surface, adhesive molecules anchor themselves while the rubber compound cures around them. At the same time, micro-roughness on the metal lets the cured elastomer key into small valleys, so the bond acts like tiny mechanical rubber products hooks plus chemical glue.

When we mold rubber onto metal inserts, we also rely on chemical cross-links that form between the rubber, the primer, and the metal treatment. Heat and pressure in the mold drive these reactions. If temperature, cure time, or primer thickness fall outside their window, the bond looks fine at first but starts to separate under real loading.

Different elastomers behave very differently on various metals, and understanding environmental exposure and accelerated testing of these bonded assemblies helps predict long-term performance:

- Natural rubber offers excellent elasticity but needs protection from oils and heat.

- Neoprene works well with steel and cast iron in oily, hot areas.

- Silicone excels on stainless parts that see extreme temperature swings.

- Aluminum and some coated steels may need special primers or conversion coatings so the adhesive can wet the surface instead of sitting on a slick film.

For industrial mounts we look beyond simple pull-off strength. We pay attention to:

- Static load capacity and deflection, which define how much the mount compresses under machine weight.

- Dynamic stiffness and hysteretic damping, which show how well the mount filters vibration at operating speed.

- Fatigue and environmental resistance, including temperature, ozone, fuel, coolants, and cleaning chemicals.

One of our senior engineers often says, “If you do not control the bond line, the bond will control you.”

Bond failure usually follows a few patterns:

- Adhesive failure happens when rubber peels cleanly away from metal.

- Cohesive failure means the rubber or adhesive tears within its own body, which points to wrong hardness or poor cure.

- Environmental attack shows up as swelling, cracking, or hardening after fluid or temperature exposure.

To avoid these issues, we at RK Rubber Enterprise Co. match elastomer type, Shore hardness, and dynamic modulus to each job so the rubber to metal bonding shares load correctly instead of being overstressed.

Selecting The Right Adhesive For Your Application

No single adhesive works best for every rubber to metal bonding job. We weigh materials, loads, temperature, fluids, and production speed before we choose a system.

Polychloroprene (Neoprene) Adhesives

Polychloroprene, or neoprene, is our main choice for demanding rubber to metal bonding, following established Rubber-to-Metal Bonding Performance guidelines that document the chemistry’s superior adhesion characteristics. High grade products deliver strong shear and peel strength from about minus thirty four to roughly one hundred forty nine degrees Celsius. That range matches many plant conditions without sudden loss of grip.

Neoprene adhesives stand up well to oil, fuel, cutting fluids, water, and sunlight, so they fit harsh industrial areas. They dry quickly yet offer a bonding window of several minutes, which lets us position inserts without rushing. Medium viscosity makes them easy to apply by brush or spray on most metal surfaces.

In our neoprene mounts for gearboxes, compressors, and CNC machines, this chemistry keeps rubber anchored to metal even under vibration. That way the mount wears in a controlled manner instead of peeling suddenly at the bond line.

Silicone Rubber Adhesives

Silicone rubber adhesives fill a more specialized role. Their main strength is very high temperature resistance while staying flexible, which makes them helpful near ovens, exhaust lines, or hot engine parts. After curing, the bond stays soft, so it can absorb movement from thermal expansion between rubber and metal without cracking. One part and two part systems are available, and formulas can be adjusted for faster cure or higher heat resistance. Shear strength is lower than neoprene, but performance under compression and heat is excellent.

Other Adhesive Options And Their Limitations

Natural rubber based adhesives can bond to metals like iron or steel in light work, and they suit materials such as wood or fabric. Their flexibility is good at room temperature, yet they soften and degrade under heat, oils, solvents, or sunlight, so we avoid them for industrial mounts.

Cyanoacrylate, or super glue, cures in seconds and gives very high initial strength on small, clean rubber and metal parts. The bond line is thin and stiff, so repeated vibration, impact, or large temperature swings can cause cracks and sudden failure.

Butyl rubber rubber adhesives shine in sealing and tire repair because they resist gas and moisture and stay tacky. For structural mounts their focus on sealing instead of carrying loads makes them weaker than neoprene systems.

To summarize common choices:

| Adhesive Type | Best Use | Main Limit |

|---|---|---|

| Neoprene | General industrial mounts | Needs clean, prepared metal |

| Silicone | High heat, thermal cycling | Lower shear strength |

| Cyanoacrylate | Small, rigid parts | Poor under vibration |

| Butyl / Natural Rubber | Sealing and light work | Not for structural loads |

Essential Surface Preparation And Bonding Techniques

When we design strong rubber to metal bonding, we start with surface cleaning. Metal inserts arrive with oil, rust, mill scale, or dust that will block adhesion if left in place. We remove these films by solvent degreasing, abrasion, or a mix of both, then keep the cleaned parts away from bare hands so new grease does not sneak back in.

A slightly rough metal surface gives the adhesive more area to grip. Grit blasting creates controlled roughness and also exposes fresh metal under surface oxides. Depending on the steel or aluminum grade, we may add conversion coatings, phosphate layers, or specialized primers that react chemically with both metal and rubber during molding.

As process engineers like to remind teams, “Clean, dry, and rough is the starting point for any reliable bond.”

Adhesive works best in a thin, even layer rather than a thick puddle. We control viscosity, mixing, and application method so the film wets the entire bonding area without runs or dry spots. Temperature and humidity in the bonding area stay within the adhesive supplier’s recommended window, because cold metal or very humid air can slow cure and trap bubbles.

After we bring the treated metal and uncured rubber together, we hold everything firmly while the adhesive cures. Proper clamping or molding pressure keeps the bond line at the right thickness and stops parts from slipping under their own weight. We also separate initial handling strength from full cure strength, since some joints need several hours before they can take full design load.

Throughout this stage, our quality team checks that bond-line thickness and surface finish stay within limits for each mount design. We inspect for voids, bubbles, and incomplete coverage at the rubber edge, where problems show up first. For hybrid designs that combine bonding and bolts, we verify joint torque so the mechanical fasteners share load correctly. We then run sample parts through temperature and hysteresis tests, following ISO 9001 procedures and ASTM or DIN methods, to confirm that actual performance matches the design model.

Conclusion

Strong rubber to metal bonding does not happen by accident. It depends on the right combination of rubber compound, metal preparation, adhesive chemistry, and controlled processing, all matched to the way the mount will actually work in service. When any of those parts is chosen on guesswork, bonds may peel, crack, or age far faster than the equipment around them.

For industrial mounts, polychloroprene neoprene adhesives give a strong mix of strength, temperature range, and resistance to oils and chemicals. Combined with the right elastomer hardness and geometry, they help mounts carry static load, manage vibration, and survive fatigue without sudden failure.

At RK Rubber Enterprise Co., we focus our design and manufacturing on bonded elastomer mounts for Philippine industries. We adjust materials, hardness, and mount shape for specific machines, loads, temperatures, and standards such as ISO 9001, ASTM, and DIN. Our testing on damping, hysteresis, and bond strength aims to extend equipment life and cut unplanned stops. When a project needs new or upgraded industrial mounts, our engineering team can review your requirements and provide recommendations and quotes.

FAQs

Question 1: What Is The Strongest Adhesive For Bonding Rubber To Metal In High-Stress Applications?

For high stress rubber to metal bonding, we normally choose high grade polychloroprene neoprene adhesives. They give high shear and peel strength, with test data reaching hundreds of psi in shear depending on temperature. These systems also handle oils, fuels, coolants, and heat well, so the bond keeps holding even when mounts work near engines or gearboxes.

Question 2: How Does Surface Preparation Affect The Longevity Of Rubber-To-Metal Bonds?

Surface preparation largely decides how long a bond will last. Removing oil, rust, and dust lets adhesive touch real metal instead of a weak film. Controlled roughness from blasting adds mechanical grip, while primers and conversion coatings build chemical bridges. At RK Rubber Enterprise Co. we inspect surfaces and bond lines carefully before and after molding.

Question 3: Can Rubber-To-Metal Mounts Withstand Extreme Temperature Fluctuations?

Yes, when we choose materials correctly, rubber to metal mounts can handle wide temperature swings. Neoprene based bonding systems work from about minus thirty four up to around one hundred forty nine degrees Celsius. We also match elastomer type and thermal expansion with the metal, then test hysteresis across the range to keep preload changes under control.

Question 4: What Makes RK Rubber Enterprise Co.’s Industrial Mounts Different From Standard Products?

Our mounts stand out through custom engineering, careful material choice, and strict quality control. We tune elastomer hardness and dynamic stiffness for each machine and environment, instead of relying on off the shelf parts. Every batch goes through dimensional checks, hardness tests, and visual inspection based on ISO 9001, ASTM, and DIN methods.

Leave a Reply

Want to join the discussion?Feel free to contribute!