Picture a new commercial tower in Metro Manila where everything looks perfect on opening day. After a few months, complaints start to pile up about humming ceilings, rattling windows, and an odd buzzing in corner offices. The HVAC equipment on the roof runs within its rated capacity, but without proper vibration isolators, every start and stop sends tiny shocks through the structure.

Those small vibrations do more than annoy tenants. They stress motors and bearings, loosen connections, crack concrete over time, and even drag down energy efficiency. Instead of running smoothly, chillers and air handling units fight against misalignment and extra friction. Maintenance teams chase leaks and noisy fans, and the equipment wears out years ahead of schedule.

We see this pattern again and again when vibration control is treated as an optional add‑on instead of part of the HVAC design. With the right vibration isolators under each unit, movement stays where it should be – inside the machine – instead of spreading into beams, floors, and walls. That means longer service life, fewer breakdowns, and lower power bills. It also supports compliance with the Philippine Electrical Code (PEC) and NFPA 110, which already recognize how serious vibration can be, especially for emergency power systems.

In this article, we walk through what vibration isolators are, why HVAC systems depend on them, how to choose the right type, and how proper isolation improves efficiency and lifespan. We also share how we at RK Rubber Enterprise Co. support projects across the Philippines with anti‑vibration pads, mounts, and spring isolators built for local conditions.

Key Takeaways

Before we go deeper, it helps to see the main points in one place. These highlights show why vibration control should stand beside capacity and efficiency in every HVAC design and upgrade plan.

- Proper vibration isolation can extend HVAC equipment life by one‑third or more, often around thirty to fifty percent. That longer life means fewer replacements, less scrap, and more predictable capital planning over many years.

- The Philippine Electrical Code and NFPA 110 call for vibration isolators on emergency power systems. When mechanical rooms combine generators and HVAC equipment, this guidance reinforces the need for proper isolation across the whole setup.

- Elastomeric and spring vibration isolators work best in different ranges of speed and weight. Matching type and rating to actual equipment data is the key to quiet, stable, and efficient operation.

- RK Rubber Enterprise Co. provides a wide range of products, from anti‑vibration rubber pads to engineered metal‑bonded mounts and spring units. This mix allows us to match the isolator design to each chiller, fan, or cooling tower instead of using a one‑size‑fits‑all part.

- Placing vibration isolators between the HVAC equipment and the foundation blocks vibration paths into the structure. This setup cuts noise, protects the building frame, and helps nearby sensitive equipment run correctly.

What Are Vibration Isolators And Why Do HVAC Systems Need Them?

Vibration isolators are engineered parts that sit between a vibrating machine and the structure that supports it. In simple terms, they act like a rubber pads, so the equipment can move slightly without sending that motion straight into beams, slabs, or steel frames. For HVAC systems, these parts are usually rubber‑based mounts, pads, or steel springs designed to work at specific loads and frequencies.

Chillers, air handling units, compressors, and cooling towers all create vibration as motors turn and fans spin. That movement tries to travel from the equipment base through anchor bolts into floors, walls, and columns. Once inside the structure, it spreads out, often showing up as noise or a faint shake far from the machine room.

HVAC equipment needs isolation for three main reasons:

- We protect the equipment itself. Vibration isolators lower the stress on motors, bearings, and compressor assemblies, which reduces misalignment, premature wear, and sudden failures—a principle supported by research on mitigation of structural vibrations in mechanical systems. With less mechanical shock, components keep their factory clearances longer, so the units stay closer to original performance.

- We protect the structural frame. Repeated vibration loads create tiny cycles of stress in concrete and steel. Over time, this can grow from hairline cracks into visible damage around bases and supports. Proper isolation keeps these pulses away from the structure, which helps maintain long‑term strength.

- We protect comfort and quiet inside occupied spaces. Without isolation, structure‑borne vibration turns into noise that travels through slabs and walls. Offices, hotel rooms, and hospital wards can all hear or feel the equipment even several floors away.

“Vibration is one of the most common causes of premature failure in rotating machinery.” — Common teaching in mechanical and rotating equipment design

Industry bodies such as EGSA and NEIS warn against bolting heavy HVAC units directly to floors or pedestals. We follow the same principle and treat vibration isolators as a standard design item, not an afterthought.

The Hidden Costs Of Poor Vibration Control In HVAC Systems

Poor vibration control rarely fails on day one. Instead, it chips away at performance, comfort, and budgets month after month. When vibration isolators are missing, undersized, or badly installed, the extra movement shows up in four costly ways.

- Premature failure and heavy maintenance.

Constant vibration punishes compressor bearings, motor mounts, and refrigerant lines. Bearings can seize, fan shafts drift out of alignment, and copper lines crack, leading to leaks. Each incident brings unplanned shutdowns, rush parts orders, and overtime labor that far exceed the cost of proper isolation.

- Lower energy efficiency.

As components wear and drift out of alignment, motors need more power to do the same work. Fans may rub or run on poor bearings, and compressors pull extra current. Systems without good isolation often run ten to twenty percent below their rated efficiency, which, at Philippine commercial power rates, adds a serious long‑term burden on operating budgets.

- Gradual structural damage.

Small vibrations create repeated stress cycles in pedestals, beams, and slabs. Micro‑cracks form around anchor points, then widen into visible damage that calls for injection, patching, or even partial rebuilding. These repair projects disrupt operations and cost much more than installing correct vibration isolators during the original works.

- Noise complaints and comfort issues.

Structure‑borne vibration can turn quiet hotel rooms into low‑hum zones and disturb patients in hospitals or residents in condominiums. Tenants may demand rent adjustments or simply move out, which affects property value. On top of that, missed code expectations under PEC Chapter 7 and NFPA 110 can create compliance questions and possible liability if damage or failure occurs.

“If you ignore vibration at commissioning, you pay for it for the rest of the building’s life.” — Saying often heard among maintenance and plant engineers

Types Of Vibration Isolators For HVAC Applications

Choosing the right type of vibration isolator starts with understanding how the HVAC unit behaves. Operating speed, weight, mounting layout, and location all guide the choice. In many building projects, we combine different isolator types so that each piece of equipment gets support that fits its actual job instead of a generic pad.

Elastomeric (Rubber) Isolators

Elastomeric vibration isolators use rubber compounds such as natural rubber, neoprene, or specially mixed blends bonded to steel plates or housings. The rubber works as a flexible layer that compresses and rebounds as the machine moves, with performance characteristics documented in numerical and experimental study of elastomeric behavior under dynamic loads. During this motion, it turns part of the vibrational energy into low‑grade heat, which reduces what reaches the structure.

These isolators work very well for higher operating speeds, where vibration frequencies usually sit above fifteen to twenty hertz. Typical HVAC uses include:

- Air handling units

- Small and medium chillers

- Fan coil units

- Packaged rooftop units

- Many compressor skids

Their compact form makes them a good match for tight mechanical rooms and roof frames with limited height.

Elastomeric mounts are budget‑friendly for moderate loads, easy to install, and effective on high‑frequency vibration from fast‑turning motors and fans. When we build anti‑vibration rubber pads at RK Rubber Enterprise Co., we use advanced compounds designed for long life, high shock absorption, and strong resistance to oils, cleaning chemicals, and weather. That mix fits well with outdoor rooftop equipment that faces Philippine sun, heat, and heavy rain.

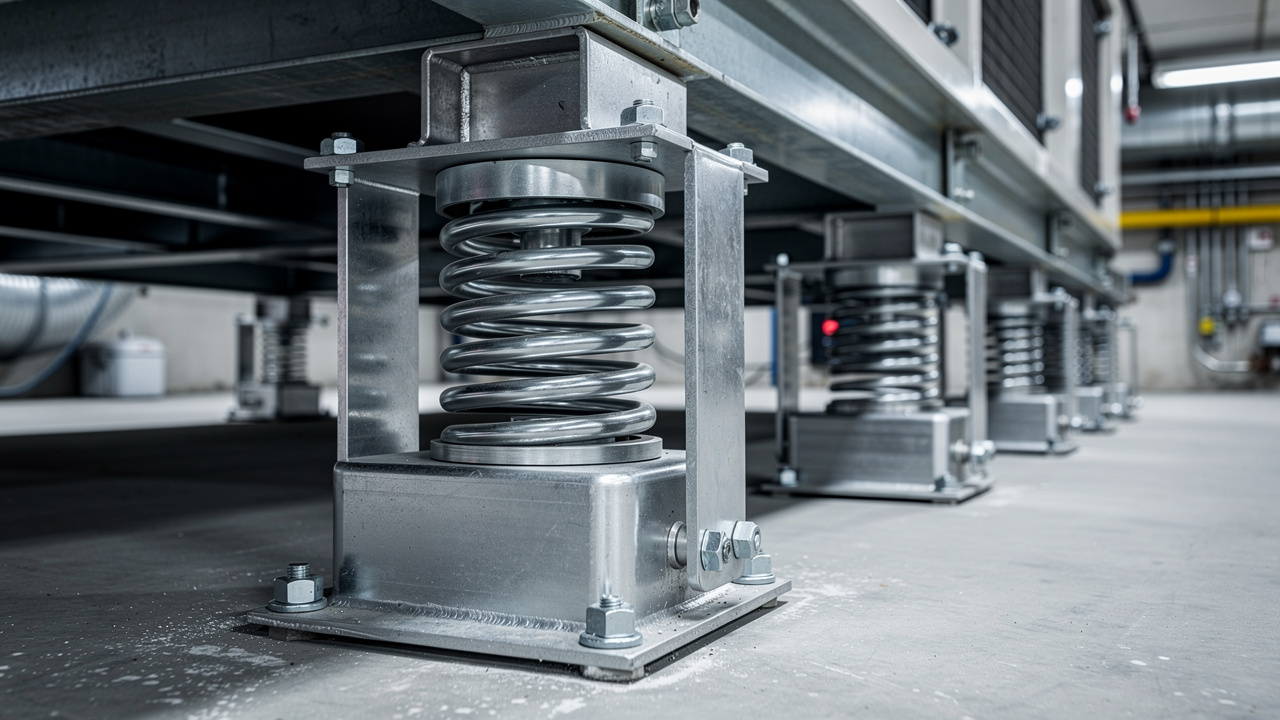

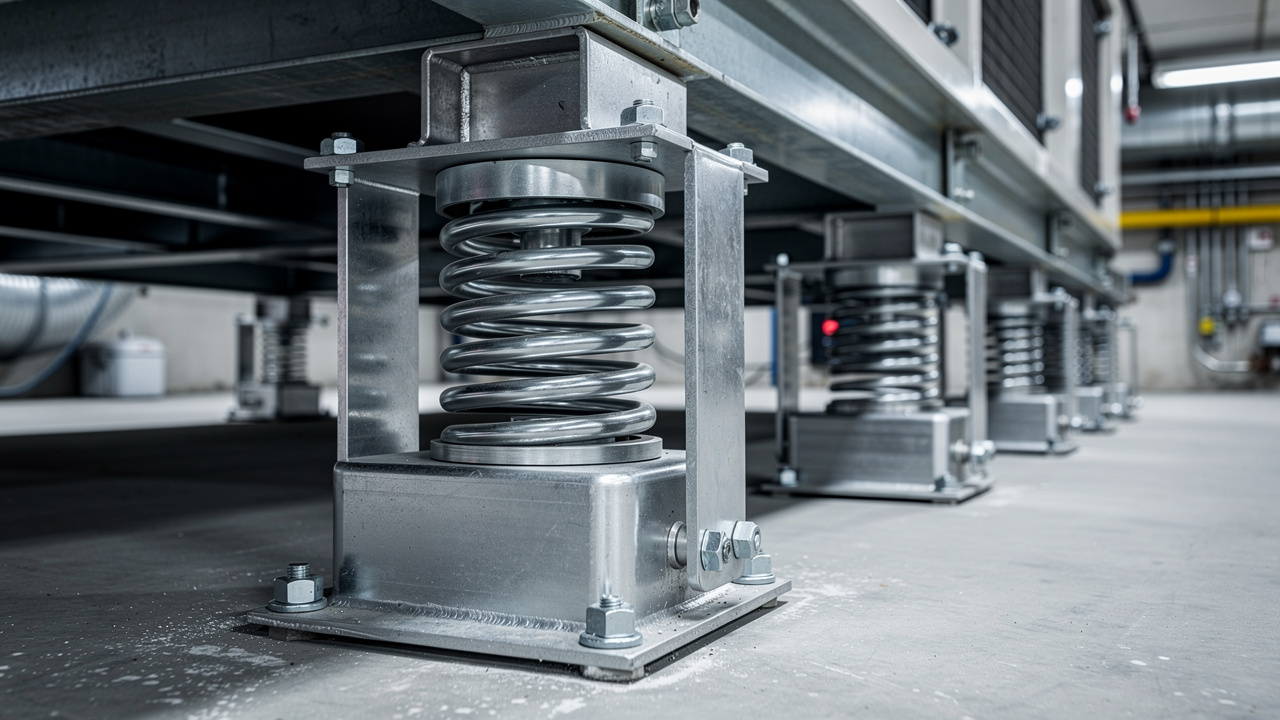

Spring Isolators

Spring vibration isolators use one or more steel coil springs inside a frame or housing. The equipment weight compresses the spring to a set deflection, which gives the system a low natural frequency. This design is especially good at cutting low‑frequency vibration from large, slow‑speed equipment where rubber alone would not give enough movement.

For HVAC work, spring isolators are common on:

- Heavy chillers

- Cooling towers

- Large air handling systems

- Big rooftop units

These machines often run at lower speeds and higher loads, so their vibration can travel deep into the structure if not handled correctly. Spring units allow greater movement while still keeping the equipment stable and level.

Key advantages include:

- Very good performance at low frequencies

- Strong load capacity for multi‑ton equipment

- Consistent behavior over a long service life

Many designs include adjustment hardware so we can fine‑tune preload and leveling after installation. At RK Rubber Enterprise Co., our spring isolators are built with low natural frequency targets and adjustable settings, which help us match each set to the actual weight and support points of the mechanical rubber products.

Specialized And Hybrid Options

Some HVAC setups need more than a single type of vibration isolator:

- Neoprene pads and strips work well where we need low‑profile support and where oil and chemical resistance matter, such as under smaller pumps or auxiliary equipment.

- Metal‑bonded elastomer mounts provide precise deflection control for equipment that must hold a strict alignment.

- Hybrid systems combine springs with elastomer layers to handle a wide spread of frequencies while still damping noise.

With RK Rubber’s customization capability, we size these parts based on real load points and contact areas rather than guesswork.

Compliance With Philippine Standards: PEC And NFPA 110 Requirements

Code compliance is not just about electrical safety. It also includes how mechanical equipment is supported and isolated. In the Philippines, the Philippine Electrical Code (PEC) places clear attention on emergency and standby power systems, which often share space and foundations with large HVAC equipment.

Chapter 7 of the PEC covers installation, testing, and maintenance for emergency systems and points directly to NFPA 110 as the main reference. This makes NFPA 110 more than a guideline; it becomes the standard that inspectors expect to see followed in hospitals, commercial buildings, and industrial plants with emergency power. Where generator sets and major HVAC equipment sit on common structures, this standard pushes the whole design toward better vibration management.

NFPA 110 Rule 7.5 states that:

“Vibration isolators, as recommended by the manufacturer of the EPS, shall be installed either between the rotating equipment and its skid base or between the skid base and the foundation or inertia base.”

In practice, that means two code‑compliant paths:

- Use isolators between the engine or alternator and the skid, often installed at the factory.

- Place isolators between the skid and the concrete base on site.

Direct bolting of generator sets or similar heavy rotating machines to the foundation fails this expectation and can lead to inspection issues. Non‑compliance may also affect equipment warranties and raise questions if structural damage or failure occurs later.

We always suggest going beyond the bare minimum by following manufacturer isolation guidance for all major HVAC units, not just emergency equipment. Our team at RK Rubber Enterprise Co. supports this process with product selection help, drawings, and data that make it easier to document compliance.

How To Select The Right Vibration Isolators For Your HVAC System

Good results start with the right data. Picking vibration isolators based only on rough weight guesses or catalog pictures often leads to underperformance. We follow a simple framework that any facility manager or engineer can use as a checklist.

Step 1 – Determine Equipment Operating Frequency

Look at fan and motor speed in revolutions per minute and convert that to hertz by dividing by sixty. Higher frequencies often point to elastomeric isolators, especially above about fifteen hertz. Lower speeds, especially on big chillers and towers, usually call for spring isolators with enough deflection to sit well below the disturbing frequency.

Step 2 – Calculate Total Load And How It Is Shared

Include the full operating weight of the HVAC unit, not just the dry weight on the nameplate. That means adding refrigerant, oil, and any accessories. Then check the base frame and mounting bolt layout to understand how this weight spreads across each isolator. Undersized mounts can bottom out, while oversized ones may not deflect enough to work properly.

Step 3 – Define The Isolation Level You Need

General comfort cooling for offices may work well with about eighty‑five to ninety percent isolation, following established vibration isolation use guidelines for commercial applications. Hospitals, data centers, and research facilities may need ninety‑five percent or more. Higher targets push designs toward spring isolators and more deflection, especially at low frequencies.

Step 4 – Consider The Environment

Philippine heat, humidity, UV exposure, and occasional flooding all affect material choice. Check for outdoor or rooftop placement, exposure to oils or chemicals, and temperature swings in mechanical rooms. Rubber compounds must stand up to these conditions without hardening or creeping.

Step 5 – Review Space And Support Limits

Available height, base footprint, and foundation capacity shape the final choice. Some spring isolation systems need more clearance, while low‑profile neoprene pads work in tight spaces. Also plan access so maintenance teams can inspect or change isolators without major disassembly.

Step 6 – Match Hardness And Dynamic Stiffness

For elastomeric mounts, Shore hardness affects how much they deflect under load and where the natural frequency sits. Dynamic stiffness tells us how the mount behaves under actual vibration, not just static weight. At RK Rubber Enterprise Co., we use this data to select or customize rubber cushion so the system avoids resonance and meets target isolation.

When customers share accurate load and layout data, we can provide clear recommendations and test information that support both performance and compliance documentation.

Measurable Benefits: How Proper Vibration Isolation Improves HVAC Performance

When vibration isolators are selected and installed correctly, the gains show up in both technical reports and financial statements. Many plants and buildings move from constant repairs to stable, predictable HVAC operation once proper isolation is in place.

Key measurable benefits include:

- Longer equipment lifespan.

With lower mechanical stress on bearings, shafts, and compressor internals, HVAC units can run thirty to fifty percent longer before major overhaul or replacement. Over a ten‑ to fifteen‑year planning window, this can keep expensive chillers and large fans in service well past the point where poorly isolated units would already be replaced.

- Lower maintenance costs.

Better isolation means fewer bearing changes, fewer refrigerant leaks due to cracked lines, and less time spent on repeated alignment work. Many facilities report maintenance savings in the range of twenty to forty percent for well‑isolated systems, along with fewer emergency callouts and less unplanned downtime during peak cooling months.

- Improved energy performance.

Machines that stay in alignment and operate on healthy bearings use less power. With proper vibration control, it is common to see five to fifteen percent better energy use compared with similar equipment installed on hard mounts. With local electricity costs, even the lower end of that range gives a strong payback.

On top of this, stable isolation supports:

- More consistent temperatures and humidity

- Fewer nuisance trips and control issues

- Quieter spaces and better comfort for occupants

- Less risk of damage to foundations and nearby sensitive equipment

RK Rubber Enterprise Co. supports these gains with high‑quality rubber compounds and tested spring designs that hold their properties over many years in Philippine conditions.

Conclusion

Good HVAC design is about more than picking the right capacity and controls. Without proper vibration isolation, even the best chiller or air handling unit can become a source of wasted energy, early failure, and ongoing complaints. Well‑chosen vibration isolators keep movement inside the machine, protect the building, and help systems run closer to their rated performance for a longer time.

By investing in quality isolation, we protect both the equipment and the structure that supports it. That means fewer major repairs, less noise in offices or hotel rooms, and a longer interval before expensive replacements appear in the budget. When we factor in lower energy use and reduced maintenance, the initial cost of good isolators often pays back many times over the life of the HVAC plant.

For facilities in the Philippines, the PEC and NFPA 110 already recognize how important proper vibration control is, especially around emergency power systems. Bringing the same care to all major HVAC equipment keeps projects safer, quieter, and easier to justify during audits and inspections. Facility managers, engineers, and contractors should review existing installations, check for proper vibration control, and specify isolation from the start on new projects.

At RK Rubber Enterprise Co., we support this work with a wide product range, from anti‑vibration rubber pads and neoprene strips to engineered metal‑bonded mounts and spring isolators. Our team helps match each product to real loads and conditions, giving customers both reliable performance and peace of mind.

FAQs

Question 1: What Is The Difference Between Elastomeric And Spring Vibration Isolators For HVAC Systems?

Elastomeric vibration isolators use rubber compounds to absorb higher‑frequency vibration, usually above fifteen to twenty hertz. They suit smaller and medium HVAC units, such as compressors, fan coil units, and packaged rooftop systems, where loads and deflections stay moderate. Spring isolators use steel coils to handle lower‑frequency vibration and heavier equipment, such as chillers and cooling towers. They provide greater deflection and better isolation for slow‑speed machines. The choice depends on operating speed, weight, and how much isolation the project needs, and RK Rubber Enterprise Co. offers both types with options for customization.

Question 2: Are Vibration Isolators Required By Law In The Philippines For HVAC Installations?

For emergency power supply systems, yes. PEC Chapter 7 points to NFPA 110, whose Rule 7.5 calls for vibration isolators between the rotating equipment and skid, or between the skid and the foundation. General HVAC equipment outside emergency systems may not always be named directly in the same way. However, manufacturers and industry groups such as EGSA and NEIS strongly discourage direct bolting without isolation. Following their guidance protects structural and equipment warranties and reduces the risk of damage or liability.

Question 3: How Do I Know What Size And Type Of Vibration Isolator I Need For My HVAC Equipment?

Sizing starts with accurate equipment data. You need the full operating weight including refrigerant, oil, and accessories; the rotating speed of fans or compressors; and the mounting layout. From there, check how weight is shared across the support points and what isolation level is needed for the space below or around the unit. Undersized isolators will compress too much and lose their function, while oversized units may not deflect enough and can cause instability. The best path is to consult manufacturer data and then work with a partner like RK Rubber Enterprise Co., where our technical team uses real load point measurements and site conditions to recommend the correct type and rating.

Question 4: Can Vibration Isolators Really Extend HVAC Equipment Lifespan And Reduce Energy Costs?

Yes, and the gains are measurable. By cutting vibration levels, you reduce wear on bearings, motors, and compressor parts, which can extend service life by thirty to fifty percent compared with rigid mounting. That same reduction in friction and misalignment often improves energy performance by about five to fifteen percent, because motors do not fight extra resistance. Maintenance needs usually drop by twenty to forty percent as leaks, bearing failures, and misalignment problems become less common. In many projects, the cost of proper vibration isolators pays back within two to three years through combined savings, especially when using RK Rubber’s durable compounds and tested designs.

Question 5: How Often Should Vibration Isolators Be Inspected Or Replaced?

We suggest at least one visual inspection each year. During this check, look for cracks, hardening, or excessive compression in rubber parts and make sure the equipment remains level on its supports. Quality elastomeric mounts often last ten to fifteen years, while well‑protected spring isolators can serve for fifteen to twenty years or more. Signs that replacement is needed include visible cracking, permanent flattening beyond design limits, and noticeable increases in transmitted vibration or noise. RK Rubber Enterprise Co. designs its products with strong resistance to weather, corrosion, and mechanical shock, which supports long service life under Philippine conditions.

Introduction

Picture a new commercial tower in Metro Manila where everything looks perfect on opening day. After a few months, complaints start to pile up about humming ceilings, rattling windows, and an odd buzzing in corner offices. The HVAC equipment on the roof runs within its rated capacity, but without proper vibration isolators, every start and stop sends tiny shocks through the structure.

Those small vibrations do more than annoy tenants. They stress motors and bearings, loosen connections, crack concrete over time, and even drag down energy efficiency. Instead of running smoothly, chillers and air handling units fight against misalignment and extra friction. Maintenance teams chase leaks and noisy fans, and the equipment wears out years ahead of schedule.

We see this pattern again and again when vibration control is treated as an optional add‑on instead of part of the HVAC design. With the right vibration isolators under each unit, movement stays where it should be – inside the machine – instead of spreading into beams, floors, and walls. That means longer service life, fewer breakdowns, and lower power bills. It also supports compliance with the Philippine Electrical Code (PEC) and NFPA 110, which already recognize how serious vibration can be, especially for emergency power systems.

In this article, we walk through what vibration isolators are, why HVAC systems depend on them, how to choose the right type, and how proper isolation improves efficiency and lifespan. We also share how we at RK Rubber Enterprise Co. support projects across the Philippines with anti‑vibration pads, mounts, and spring isolators built for local conditions.

Key Takeaways

Before we go deeper, it helps to see the main points in one place. These highlights show why vibration control should stand beside capacity and efficiency in every HVAC design and upgrade plan.

- Proper vibration isolation can extend HVAC equipment life by one‑third or more, often around thirty to fifty percent. That longer life means fewer replacements, less scrap, and more predictable capital planning over many years.

- The Philippine Electrical Code and NFPA 110 call for vibration isolators on emergency power systems. When mechanical rooms combine generators and HVAC equipment, this guidance reinforces the need for proper isolation across the whole setup.

- Elastomeric and spring vibration isolators work best in different ranges of speed and weight. Matching type and rating to actual equipment data is the key to quiet, stable, and efficient operation.

- RK Rubber Enterprise Co. provides a wide range of products, from anti‑vibration rubber pads to engineered metal‑bonded mounts and spring units. This mix allows us to match the isolator design to each chiller, fan, or cooling tower instead of using a one‑size‑fits‑all part.

- Placing vibration isolators between the HVAC equipment and the foundation blocks vibration paths into the structure. This setup cuts noise, protects the building frame, and helps nearby sensitive equipment run correctly.

What Are Vibration Isolators And Why Do HVAC Systems Need Them?

Vibration isolators are engineered parts that sit between a vibrating machine and the structure that supports it. In simple terms, they act like a rubber pads, so the equipment can move slightly without sending that motion straight into beams, slabs, or steel frames. For HVAC systems, these parts are usually rubber‑based mounts, pads, or steel springs designed to work at specific loads and frequencies.

Chillers, air handling units, compressors, and cooling towers all create vibration as motors turn and fans spin. That movement tries to travel from the equipment base through anchor bolts into floors, walls, and columns. Once inside the structure, it spreads out, often showing up as noise or a faint shake far from the machine room.

HVAC equipment needs isolation for three main reasons:

- We protect the equipment itself. Vibration isolators lower the stress on motors, bearings, and compressor assemblies, which reduces misalignment, premature wear, and sudden failures—a principle supported by research on mitigation of structural vibrations in mechanical systems. With less mechanical shock, components keep their factory clearances longer, so the units stay closer to original performance.

- We protect the structural frame. Repeated vibration loads create tiny cycles of stress in concrete and steel. Over time, this can grow from hairline cracks into visible damage around bases and supports. Proper isolation keeps these pulses away from the structure, which helps maintain long‑term strength.

- We protect comfort and quiet inside occupied spaces. Without isolation, structure‑borne vibration turns into noise that travels through slabs and walls. Offices, hotel rooms, and hospital wards can all hear or feel the equipment even several floors away.

“Vibration is one of the most common causes of premature failure in rotating machinery.” — Common teaching in mechanical and rotating equipment design

Industry bodies such as EGSA and NEIS warn against bolting heavy HVAC units directly to floors or pedestals. We follow the same principle and treat vibration isolators as a standard design item, not an afterthought.

The Hidden Costs Of Poor Vibration Control In HVAC Systems

Poor vibration control rarely fails on day one. Instead, it chips away at performance, comfort, and budgets month after month. When vibration isolators are missing, undersized, or badly installed, the extra movement shows up in four costly ways.

- Premature failure and heavy maintenance.

Constant vibration punishes compressor bearings, motor mounts, and refrigerant lines. Bearings can seize, fan shafts drift out of alignment, and copper lines crack, leading to leaks. Each incident brings unplanned shutdowns, rush parts orders, and overtime labor that far exceed the cost of proper isolation.

- Lower energy efficiency.

As components wear and drift out of alignment, motors need more power to do the same work. Fans may rub or run on poor bearings, and compressors pull extra current. Systems without good isolation often run ten to twenty percent below their rated efficiency, which, at Philippine commercial power rates, adds a serious long‑term burden on operating budgets.

- Gradual structural damage.

Small vibrations create repeated stress cycles in pedestals, beams, and slabs. Micro‑cracks form around anchor points, then widen into visible damage that calls for injection, patching, or even partial rebuilding. These repair projects disrupt operations and cost much more than installing correct vibration isolators during the original works.

- Noise complaints and comfort issues.

Structure‑borne vibration can turn quiet hotel rooms into low‑hum zones and disturb patients in hospitals or residents in condominiums. Tenants may demand rent adjustments or simply move out, which affects property value. On top of that, missed code expectations under PEC Chapter 7 and NFPA 110 can create compliance questions and possible liability if damage or failure occurs.

“If you ignore vibration at commissioning, you pay for it for the rest of the building’s life.” — Saying often heard among maintenance and plant engineers

Types Of Vibration Isolators For HVAC Applications

Choosing the right type of vibration isolator starts with understanding how the HVAC unit behaves. Operating speed, weight, mounting layout, and location all guide the choice. In many building projects, we combine different isolator types so that each piece of equipment gets support that fits its actual job instead of a generic pad.

Elastomeric (Rubber) Isolators

Elastomeric vibration isolators use rubber compounds such as natural rubber, neoprene, or specially mixed blends bonded to steel plates or housings. The rubber works as a flexible layer that compresses and rebounds as the machine moves, with performance characteristics documented in numerical and experimental study of elastomeric behavior under dynamic loads. During this motion, it turns part of the vibrational energy into low‑grade heat, which reduces what reaches the structure.

These isolators work very well for higher operating speeds, where vibration frequencies usually sit above fifteen to twenty hertz. Typical HVAC uses include:

- Air handling units

- Small and medium chillers

- Fan coil units

- Packaged rooftop units

- Many compressor skids

Their compact form makes them a good match for tight mechanical rooms and roof frames with limited height.

Elastomeric mounts are budget‑friendly for moderate loads, easy to install, and effective on high‑frequency vibration from fast‑turning motors and fans. When we build anti‑vibration rubber pads at RK Rubber Enterprise Co., we use advanced compounds designed for long life, high shock absorption, and strong resistance to oils, cleaning chemicals, and weather. That mix fits well with outdoor rooftop equipment that faces Philippine sun, heat, and heavy rain.

Spring Isolators

Spring vibration isolators use one or more steel coil springs inside a frame or housing. The equipment weight compresses the spring to a set deflection, which gives the system a low natural frequency. This design is especially good at cutting low‑frequency vibration from large, slow‑speed equipment where rubber alone would not give enough movement.

For HVAC work, spring isolators are common on:

- Heavy chillers

- Cooling towers

- Large air handling systems

- Big rooftop units

These machines often run at lower speeds and higher loads, so their vibration can travel deep into the structure if not handled correctly. Spring units allow greater movement while still keeping the equipment stable and level.

Key advantages include:

- Very good performance at low frequencies

- Strong load capacity for multi‑ton equipment

- Consistent behavior over a long service life

Many designs include adjustment hardware so we can fine‑tune preload and leveling after installation. At RK Rubber Enterprise Co., our spring isolators are built with low natural frequency targets and adjustable settings, which help us match each set to the actual weight and support points of the mechanical rubber products.

Specialized And Hybrid Options

Some HVAC setups need more than a single type of vibration isolator:

- Neoprene pads and strips work well where we need low‑profile support and where oil and chemical resistance matter, such as under smaller pumps or auxiliary equipment.

- Metal‑bonded elastomer mounts provide precise deflection control for equipment that must hold a strict alignment.

- Hybrid systems combine springs with elastomer layers to handle a wide spread of frequencies while still damping noise.

With RK Rubber’s customization capability, we size these parts based on real load points and contact areas rather than guesswork.

Compliance With Philippine Standards: PEC And NFPA 110 Requirements

Code compliance is not just about electrical safety. It also includes how mechanical equipment is supported and isolated. In the Philippines, the Philippine Electrical Code (PEC) places clear attention on emergency and standby power systems, which often share space and foundations with large HVAC equipment.

Chapter 7 of the PEC covers installation, testing, and maintenance for emergency systems and points directly to NFPA 110 as the main reference. This makes NFPA 110 more than a guideline; it becomes the standard that inspectors expect to see followed in hospitals, commercial buildings, and industrial plants with emergency power. Where generator sets and major HVAC equipment sit on common structures, this standard pushes the whole design toward better vibration management.

NFPA 110 Rule 7.5 states that:

“Vibration isolators, as recommended by the manufacturer of the EPS, shall be installed either between the rotating equipment and its skid base or between the skid base and the foundation or inertia base.”

In practice, that means two code‑compliant paths:

- Use isolators between the engine or alternator and the skid, often installed at the factory.

- Place isolators between the skid and the concrete base on site.

Direct bolting of generator sets or similar heavy rotating machines to the foundation fails this expectation and can lead to inspection issues. Non‑compliance may also affect equipment warranties and raise questions if structural damage or failure occurs later.

We always suggest going beyond the bare minimum by following manufacturer isolation guidance for all major HVAC units, not just emergency equipment. Our team at RK Rubber Enterprise Co. supports this process with product selection help, drawings, and data that make it easier to document compliance.

How To Select The Right Vibration Isolators For Your HVAC System

Good results start with the right data. Picking vibration isolators based only on rough weight guesses or catalog pictures often leads to underperformance. We follow a simple framework that any facility manager or engineer can use as a checklist.

Step 1 – Determine Equipment Operating Frequency

Look at fan and motor speed in revolutions per minute and convert that to hertz by dividing by sixty. Higher frequencies often point to elastomeric isolators, especially above about fifteen hertz. Lower speeds, especially on big chillers and towers, usually call for spring isolators with enough deflection to sit well below the disturbing frequency.

Step 2 – Calculate Total Load And How It Is Shared

Include the full operating weight of the HVAC unit, not just the dry weight on the nameplate. That means adding refrigerant, oil, and any accessories. Then check the base frame and mounting bolt layout to understand how this weight spreads across each isolator. Undersized mounts can bottom out, while oversized ones may not deflect enough to work properly.

Step 3 – Define The Isolation Level You Need

General comfort cooling for offices may work well with about eighty‑five to ninety percent isolation, following established vibration isolation use guidelines for commercial applications. Hospitals, data centers, and research facilities may need ninety‑five percent or more. Higher targets push designs toward spring isolators and more deflection, especially at low frequencies.

Step 4 – Consider The Environment

Philippine heat, humidity, UV exposure, and occasional flooding all affect material choice. Check for outdoor or rooftop placement, exposure to oils or chemicals, and temperature swings in mechanical rooms. Rubber compounds must stand up to these conditions without hardening or creeping.

Step 5 – Review Space And Support Limits

Available height, base footprint, and foundation capacity shape the final choice. Some spring isolation systems need more clearance, while low‑profile neoprene pads work in tight spaces. Also plan access so maintenance teams can inspect or change isolators without major disassembly.

Step 6 – Match Hardness And Dynamic Stiffness

For elastomeric mounts, Shore hardness affects how much they deflect under load and where the natural frequency sits. Dynamic stiffness tells us how the mount behaves under actual vibration, not just static weight. At RK Rubber Enterprise Co., we use this data to select or customize rubber cushion so the system avoids resonance and meets target isolation.

When customers share accurate load and layout data, we can provide clear recommendations and test information that support both performance and compliance documentation.

Measurable Benefits: How Proper Vibration Isolation Improves HVAC Performance

When vibration isolators are selected and installed correctly, the gains show up in both technical reports and financial statements. Many plants and buildings move from constant repairs to stable, predictable HVAC operation once proper isolation is in place.

Key measurable benefits include:

- Longer equipment lifespan.

With lower mechanical stress on bearings, shafts, and compressor internals, HVAC units can run thirty to fifty percent longer before major overhaul or replacement. Over a ten‑ to fifteen‑year planning window, this can keep expensive chillers and large fans in service well past the point where poorly isolated units would already be replaced.

- Lower maintenance costs.

Better isolation means fewer bearing changes, fewer refrigerant leaks due to cracked lines, and less time spent on repeated alignment work. Many facilities report maintenance savings in the range of twenty to forty percent for well‑isolated systems, along with fewer emergency callouts and less unplanned downtime during peak cooling months.

- Improved energy performance.

Machines that stay in alignment and operate on healthy bearings use less power. With proper vibration control, it is common to see five to fifteen percent better energy use compared with similar equipment installed on hard mounts. With local electricity costs, even the lower end of that range gives a strong payback.

On top of this, stable isolation supports:

- More consistent temperatures and humidity

- Fewer nuisance trips and control issues

- Quieter spaces and better comfort for occupants

- Less risk of damage to foundations and nearby sensitive equipment

RK Rubber Enterprise Co. supports these gains with high‑quality rubber compounds and tested spring designs that hold their properties over many years in Philippine conditions.

Conclusion

Good HVAC design is about more than picking the right capacity and controls. Without proper vibration isolation, even the best chiller or air handling unit can become a source of wasted energy, early failure, and ongoing complaints. Well‑chosen vibration isolators keep movement inside the machine, protect the building, and help systems run closer to their rated performance for a longer time.

By investing in quality isolation, we protect both the equipment and the structure that supports it. That means fewer major repairs, less noise in offices or hotel rooms, and a longer interval before expensive replacements appear in the budget. When we factor in lower energy use and reduced maintenance, the initial cost of good isolators often pays back many times over the life of the HVAC plant.

For facilities in the Philippines, the PEC and NFPA 110 already recognize how important proper vibration control is, especially around emergency power systems. Bringing the same care to all major HVAC equipment keeps projects safer, quieter, and easier to justify during audits and inspections. Facility managers, engineers, and contractors should review existing installations, check for proper vibration control, and specify isolation from the start on new projects.

At RK Rubber Enterprise Co., we support this work with a wide product range, from anti‑vibration rubber pads and neoprene strips to engineered metal‑bonded mounts and spring isolators. Our team helps match each product to real loads and conditions, giving customers both reliable performance and peace of mind.

FAQs

Question 1: What Is The Difference Between Elastomeric And Spring Vibration Isolators For HVAC Systems?

Elastomeric vibration isolators use rubber compounds to absorb higher‑frequency vibration, usually above fifteen to twenty hertz. They suit smaller and medium HVAC units, such as compressors, fan coil units, and packaged rooftop systems, where loads and deflections stay moderate. Spring isolators use steel coils to handle lower‑frequency vibration and heavier equipment, such as chillers and cooling towers. They provide greater deflection and better isolation for slow‑speed machines. The choice depends on operating speed, weight, and how much isolation the project needs, and RK Rubber Enterprise Co. offers both types with options for customization.

Question 2: Are Vibration Isolators Required By Law In The Philippines For HVAC Installations?

For emergency power supply systems, yes. PEC Chapter 7 points to NFPA 110, whose Rule 7.5 calls for vibration isolators between the rotating equipment and skid, or between the skid and the foundation. General HVAC equipment outside emergency systems may not always be named directly in the same way. However, manufacturers and industry groups such as EGSA and NEIS strongly discourage direct bolting without isolation. Following their guidance protects structural and equipment warranties and reduces the risk of damage or liability.

Question 3: How Do I Know What Size And Type Of Vibration Isolator I Need For My HVAC Equipment?

Sizing starts with accurate equipment data. You need the full operating weight including refrigerant, oil, and accessories; the rotating speed of fans or compressors; and the mounting layout. From there, check how weight is shared across the support points and what isolation level is needed for the space below or around the unit. Undersized isolators will compress too much and lose their function, while oversized units may not deflect enough and can cause instability. The best path is to consult manufacturer data and then work with a partner like RK Rubber Enterprise Co., where our technical team uses real load point measurements and site conditions to recommend the correct type and rating.

Question 4: Can Vibration Isolators Really Extend HVAC Equipment Lifespan And Reduce Energy Costs?

Yes, and the gains are measurable. By cutting vibration levels, you reduce wear on bearings, motors, and compressor parts, which can extend service life by thirty to fifty percent compared with rigid mounting. That same reduction in friction and misalignment often improves energy performance by about five to fifteen percent, because motors do not fight extra resistance. Maintenance needs usually drop by twenty to forty percent as leaks, bearing failures, and misalignment problems become less common. In many projects, the cost of proper vibration isolators pays back within two to three years through combined savings, especially when using RK Rubber’s durable compounds and tested designs.

Question 5: How Often Should Vibration Isolators Be Inspected Or Replaced?

We suggest at least one visual inspection each year. During this check, look for cracks, hardening, or excessive compression in rubber parts and make sure the equipment remains level on its supports. Quality elastomeric mounts often last ten to fifteen years, while well‑protected spring isolators can serve for fifteen to twenty years or more. Signs that replacement is needed include visible cracking, permanent flattening beyond design limits, and noticeable increases in transmitted vibration or noise. RK Rubber Enterprise Co. designs its products with strong resistance to weather, corrosion, and mechanical shock, which supports long service life under Philippine conditions.

Reliable Rubber Manufacturer in the Philippines

in Rubber ProductIntroduction

One small rubber pad or gasket can shut down an entire production line when it fails. That is why choosing a reliable rubber manufacturer in the Philippines never feels like a simple price comparison. Every decision touches safety, uptime, and long-term cost, even if the part itself looks small and ordinary.

For industrial plants, construction sites, commercial buildings, and automotive lines, rubber parts carry heavy responsibility. Bridge bearing pads hold massive structures, seals keep corrosive fluids where they belong, and dock fenders protect ships and piers from damage. When these parts fail, projects stall, schedules slip, and repair costs rise fast. In many cases, the part itself is inexpensive, but the downtime it causes is not.

We built RK Rubber Enterprise Co. around that reality. As a leading and reliable rubber manufacturer in the Philippines, we focus on more than just making parts. We combine material expertise, careful engineering, strict quality checks, and fast, responsive service. In this article, we share what truly defines a reliable rubber supplier, walk through our wide product range, and explain how our customer-first way of working helps projects finish safely, on time, and with less stress.

Key Takeaways

A reliable rubber manufacturer does more than ship parts on time. The right partner combines strong product quality, wide customization options, and hands-on customer support. This mix keeps your equipment safe, stable, and running longer.

RK Rubber Enterprise Co. serves civil engineering, marine, industrial, automotive, and commercial projects across the country. Our wide catalog and custom work let many teams source what they need from one reliable rubber supplier. That saves time and cuts coordination issues during planning and purchasing.

Our team understands rubber compounds in depth and follows strict standards such as ISO 9001, ASTM, DIN, and FDA for food-grade items. This mix of knowledge and standards helps each rubber part match its real-world job, from high temperature lines to heavy structural loads.

We have proven reliability on large projects like the Cebu Cordova Link Expressway, where we supplied elastomeric bearing pads. Along with project experience, we offer flexible service, expert consultation, and nationwide coverage, which makes us a trusted partner from NCR to Visayas and Mindanao.

What Makes RK Rubber Enterprise Co. A Reliable Rubber Manufacturer In The Philippines

When we talk about reliability, we do not stop at long-lasting parts. For us, a reliable rubber manufacturer in the Philippines must combine consistent quality, clear communication, technical guidance, and support that stays strong from design up to installation and after-sales.

Quality starts with the compounds we use. We source high grade natural and synthetic rubbers and match each material to its job, from heat resistant silicone and Viton to weather resistant EPDM and oil resistant nitrile. In our plant, we follow strict process controls and apply international standards such as ISO 9001, ASTM, DIN, and FDA for food-related parts. At every stage, we run inspections so each batch meets the mechanical and chemical performance that the application needs.

Typical checks include:

Material checks for hardness, elasticity, and basic physical properties

Dimensional checks against drawings and tolerances

Visual inspection to spot surface defects, bubbles, or cracks

We also work with a zero defect mindset. Our teams check molds, curing conditions, and dimensions again and again, so items can handle extreme temperatures, constant vibration, impact, chemicals, and outdoor exposure. This care is the reason our elastomeric bridge bearing pads help carry major structures and why many clients treat our parts as safety components, not just consumables.

Customization is another pillar of our reliability. Many projects cannot use off-the-shelf items, so we adjust rubber strips, rubber pads, rubber bushings, profiles, rubber end caps, rubber footings, and gaskets to match exact drawings. We can change material type, size, shape, color, and hardness to fit your load, movement, and sealing needs. This is how we support both one-off special parts and repeat OEM orders.

Behind that flexibility stands a state-of-the-art facility that handles bulk orders without cutting corners on quality. We plan capacity carefully, keep common compounds ready, and structure our lines so we can serve urgent requirements. By combining efficient production with competitive pricing, we give clients cost-effective options while still delivering reliable rubber products that stand up under real stress.

Our track record includes major projects like the Cebu Cordova Link Expressway, where we supplied elastomeric bearing pads that carry massive loads and reduce vibration on the bridge. That kind of work shows how we perform as a reliable rubber supplier in NCR and across the Philippines, even when the technical bar is set very high.

Comprehensive Rubber Product Range For Many Industries

We position RK Rubber Enterprise Co. as a one-stop, reliable rubber supplier for many sectors in the Philippines. From infrastructure to food plants, our aim is simple. We want clients to find the right part with one partner, backed by strong technical support and consistent quality.

To give a quick overview, here is how our products support different sectors:

Sector

Key Rubber Products From RK Rubber

Main Uses And Benefits

Civil Engineering & Construction

Elastomeric bearing pads, expansion joint fillers, water stoppers, column and corner guards

Load transfer, movement control, sealing, and impact protection

Marine & Port

Dock fenders, TEE head mooring bollards, gate seals

Impact absorption, mooring safety, and leak control

Industrial & Manufacturing

Conveyor belts, rollers, gaskets, linings, sanitizing mats

Material handling, equipment protection, and hygiene

Mechanical & Automotive

Hoses, bushings, O-rings, wheel chocks, window seals

Fluid transfer, vibration isolation, and vehicle safety

For civil engineering and construction, we provide elastomeric bridge bearing pads, including steel laminated types that manage load transfer and movement in bridges and flyovers. We also produce expansion joint fillers, rubber water stoppers, gate seals, and compressible pads that keep structures sealed and able to move without cracking. In parking areas, warehouses, and loading bays, our rubber column guards, corner guards, rubber bumpers, stair nosing, and matting help protect both people and structures.

For marine and port work, we manufacture dock fenders in many designs such as arch, V type, cell type, D type, and T type, along with unit elements. These parts absorb heavy impact between vessel and pier. We also supply TEE head mooring bollards that hold massive mooring forces and gate seals that help keep dry docks and water control points tight against leaks.

In industrial and manufacturing plants, we support material handling and equipment safety. Our product line includes conveyor belts, polyurethane wheels, rubber rollers, footings, blocks, and boxes that reduce vibration and protect machines. We also supply silicone rubber gaskets, rubber grommets, W type and J type seals, rubber linings for tanks and chutes, rubber finger pluckers for poultry plants, and sanitizing rubber foot mats for clean areas. Each item is built from the right compound to stand up to abrasion, chemicals, or constant motion.

For mechanical, automotive, and related sectors, we produce industrial reinforced, automotive, and food-grade hoses, along with bushings, bellows, O-rings, piston rings, end caps, duct plugs, ramps, and window seals. Our rubber wheel chocks and wheel guards help keep vehicles safe on slopes and in tight spaces. Across these lines, we offer wide customization, so nearly every product can match specific size, pressure, or movement requirements for your plant or project.

Our Customer-Centered Approach, Expert Support, And Flexible Service

We believe reliability should be felt not only in the product but also in the way we work with clients. That is why we treat each project as a partnership, not just a purchase order. From the first call, we listen to your goals, site conditions, and limits on time or budget, then we build a clear plan together.

Our consultation work is hands-on. We often start with drawings, sketches, or even a worn-out sample part, then discuss real operating conditions such as load, temperature, movement, and chemicals. From there, our team suggests the best compounds, whether that means natural rubber for high resilience, nitrile for oil contact, silicone for extreme heat, EPDM for outdoor exposure, Neoprene for balanced performance, or Viton for aggressive chemicals. This helps you avoid material mistakes that can cause early failure.

A typical project with RK Rubber Enterprise Co. may involve:

Initial discussion of drawings, samples, and site conditions

Material and design review based on load, movement, and temperature

Quotation and lead time confirmation, aligned with your schedule

Production, inspection, and delivery with status updates along the way

After-sales support for installation questions and performance feedback

Changes are normal in construction and industrial work, so we keep our process flexible. When clients adjust dimensions, hardness, or delivery dates, we do our best to adapt without hurting quality or schedules. Our production and sales teams work closely, which helps us keep control even when urgent orders come in or site conditions shift.

We also add value beyond manufacturing. Our engineers assist with product specifications, installation guidance for items like bearing pads, dock fenders, and water stoppers, and checks during and after delivery. We treat on-time delivery as part of quality, because even the best part is not helpful if it arrives too late for a pour or shutdown.

RK Rubber Enterprise Co. serves clients nationwide from our headquarters in Quezon City, making us a reliable rubber supplier in NCR and nearby provinces. Our Cebu office supports Visayas and Mindanao projects for faster response, easier coordination, and local insight. Over the years, this customer centered way of working has helped us build long-term ties with industrial plants, contractors, and facility managers across the Philippines.

Conclusion

Choosing the right partner for rubber parts means trusting them with safety, uptime, and project timelines. As a reliable rubber manufacturer in the Philippines, we base that trust on three pillars. We focus on strong quality and material control, a wide product range that fits many industries, and customer support that stays active from design to installation and beyond.

By working with RK Rubber Enterprise Co., you gain a team that delivers consistent results, meets tight deadlines, and shares clear technical guidance at every step. Our work on major infrastructure such as the Cebu Cordova Link Expressway shows that we can handle demanding projects with high load, vibration, and safety requirements.

Our goal is to be more than a vendor. We aim to be a partner who helps you reduce risk and reach your targets, whether your project is in NCR, Visayas, Mindanao, or any other part of the country. Reach out to us to request a product catalog, schedule a consultation, or discuss a specific rubber requirement with our team. Experience the difference of working with a truly reliable rubber supplier that combines quality products with attentive service to support your business goals.

FAQs

Question 1: What Makes RK Rubber Enterprise Co. A Reliable Rubber Manufacturer Compared To Other Suppliers In The Philippines?

We stand out by combining strong product quality, deep material knowledge, and close support before and after delivery. Our processes follow international references such as ISO 9001, ASTM, DIN, and FDA for food-grade items, and we use premium compounds matched to each job. We have supplied demanding projects like the Cebu Cordova Link Expressway, which tested our design and production strength. With nationwide coverage and a Cebu office for Visayas and Mindanao, we handle tight deadlines while keeping service personal and responsive.

Question 2: What Types Of Rubber Products Does RK Rubber Manufacture?

We produce a wide range of industrial rubber parts, including seals, gaskets, bumpers, shock absorbers, strips, pads, bushings, profiles, tubing, end caps, and rubber balls. Our catalog also covers industrial hoses for food-grade, reinforced, and automotive use, along with protective items like rubber footings, linings, column guards, and dock fenders. Many of these items are designed to deliver long service in harsh environments such as plants, ports, and roads. For most product lines, we can adjust design and material to match the real needs of your application.

Question 3: Can RK Rubber Customize Rubber Products For Specific Industrial Applications?

Yes, customization is one of our main strengths. We adjust almost every product line, from gaskets and seals to pads, bushings, and hoses, based on your drawings or samples. Options include different rubber compounds, sizes, shapes, surface textures, colors, and hardness levels to match load, movement, and temperature needs. Our team works closely with engineers and buyers to design and produce precision molded parts, including OEM components for equipment builders.

Question 4: Does RK Rubber Serve Clients Outside The National Capital Region (NCR)?

We serve clients throughout the Philippines. Our main office and plant in Quezon City handle projects in NCR and nearby regions, while our Cebu office focuses on Visayas and Mindanao. This setup helps us provide faster communication, better logistics planning, and more direct support, no matter where your project or facility is located.

Question 5: What Quality Standards Does RK Rubber Adhere To?

We base our quality system on international standards such as ISO 9001, ASTM, and DIN, and follow FDA related requirements for food-grade products. Our process includes strict checks at each production step, from raw material selection to final inspection, guided by a zero defect mindset. We use high grade compounds and controlled curing methods so our rubber products stay safe, reliable, and ready for demanding service conditions.

Trusted Rubber Manufacturer in the Philippines

in Rubber ProductOne weak rubber gasket can stop an entire production line. One worn-out rubber bushing can shut down a conveyor, delay deliveries, and push costs higher. That is why choosing a trusted rubber manufacturer is not just a purchase decision; it is a risk management decision that affects safety, uptime, and profit.

We built RK Rubber Enterprise Co. around this reality. As one of the most trusted rubber manufacturing partners in the Philippines, we focus on engineered rubber parts that keep plants, vehicles, and structures running safely and reliably. Our vision is to act as a real catalyst for Philippine industry and help our country stand as a major exporter of quality rubber products, not just a buyer.

Our team designs and produces sealing parts, shock and vibration control items, and specialized components for industrial, automotive, construction, marine, and many other applications. We support these with strict quality control based on global standards such as ISO 9001, ASTM, DIN, FDA, and RoHS, so clients can verify how we work, not just rely on promises. As a trusted rubber supplier, we also share technical know-how to help prevent design and installation errors.

In this article, we walk through what really defines a trusted rubber manufacturer in the Philippines and how we stand out. We explain our product range, how we address common industrial problems, and why many leaders treat us as a long-term partner instead of a simple vendor. By the end, you will see how working with the right trusted rubber manufacturer can protect your operations and lower your total cost over time.

Key Takeaways

What Defines A Trusted Rubber Manufacturer In The Philippines?

When plant managers and engineers talk about a trusted rubber manufacturer, they are talking about more than just a company that ships parts on time. Trust in manufacturing means:

For us, this starts with quality and reliability. We choose high-grade compounds such as EPDM, Silicone, Viton, and Nitrile, and we match them carefully to each application. Every stage of production goes through dimensional checks, hardness tests, and visual inspections under a zero-defect mindset. As a trusted rubber manufacturer in the Philippines, we follow international standards like ISO 9001, ASTM, DIN, FDA, and RoHS so clients can trace how every product was made and confirm that specifications were followed.

Safety and environmental care are also core pillars. Our rubber bumpers, pads, seals, and bushings are designed to protect both people and equipment under heat, chemicals, movement, and heavy load. At the same time, we follow Philippine regulations and apply cleaner practices in our plant, with waste reduction and responsible material handling. This helps us act as a trusted manufacturer for companies that care about both worker safety and environmental impact.

Real trust grows over time. A trusted rubber manufacturer shows a record of serving many kinds of industries, from automotive OEMs to construction and marine projects across NCR, Visayas, and Mindanao. When rubber products last longer, machines fail less, and sites stay safe, clients see lower downtime, lower total cost of ownership, and better project results. That is the standard we work toward in every order.

Our Comprehensive Range Of Industrial Rubber Products

As a trusted rubber manufacturer, we do not think of our products as simple parts on a list. We design them as working answers to sealing, safety, and performance issues that plant managers and engineers face every day. Across all categories, we provide customization so each part fits the job, not the other way around. This is what helps us act as a true trusted rubber supplier instead of a generic source.

We provide sealing parts that protect against leaks, contamination, and pressure loss. Key products include:

Our door and gate seals use EPDM, Natural Rubber, SBR, and other blends to keep water, dust, and noise under control across industrial plants, commercial buildings, and residential projects. We also design rubber piston rings that limit gas leakage and wear inside engines and cylinders, which helps extend equipment life and maintain performance over longer operating hours. As a trusted rubber manufacturer in the Philippines, we build each of these sealing parts with long-term performance in mind, not just first-day fit.

Shock and vibration control is another key part of our work. We produce rubber bushings for automotive suspension, construction machines, industrial equipment, and marine hardware to stabilize movement and absorb impact. Our shock absorbers, rubber cushion, rectangular bumpers, rubber pads, and rubber footings help protect floors, frames, and people from repeated shocks and loud vibration. These products support safer workplaces, higher worker comfort, and longer life for motors, bearings, and structures.

We also cover specialized rubber components needed in more focused applications, such as:

Across all these groups, we keep customization open so every client can get parts that match their exact drawings and requirements.

How We Address Critical Industrial Challenges

Every plant, project site, or assembly line has its own pain points, and a trusted rubber manufacturer must help remove them, not add new ones. When we talk with plant managers, project engineers, and buyers, we focus first on what keeps them up at night. Only then do we decide which rubber parts, compounds, or designs will give the best answer.

The most common challenges we see include:

Many facilities work with extreme temperatures and aggressive chemicals. For these cases, our silicone rubber gaskets handle heat up to 250°C and resist oils, steam, and strong cleaning agents, which suits power generation, petrochemical, and food-grade systems. We also help prevent sealing failures by using well-designed rubber profiles, strips, and piston rings that keep leakage low, reduce unplanned shutdowns, and cut the need for constant maintenance work. This is where a trusted rubber manufacturer can save far more money than the basic cost of the part.

Movement and safety bring another set of challenges. In construction and water infrastructure, our rubber water stoppers provide the flexibility that metal stoppers cannot match, so joints can move without cracking. To reduce workplace hazards, our cushions and pads cut vibration and noise around heavy equipment, which supports worker safety and comfort. When clients bring in highly specific needs, we adjust sizes, shapes, colors, hardness levels, and material mixes to match those demands. We do this through close discussion, drawings, and testing, which turns us into a trusted rubber supplier and problem-solving partner, not just a catalog.

Why Industrial Leaders Choose RK Rubber Enterprise Co.

When we speak with industrial leaders, many say they do not want just any rubber vendor. They want a trusted rubber manufacturer that stands with them from design to installation and beyond. We built RK Rubber Enterprise Co. around that kind of relationship, so our role is closer to a technical partner than a simple vendor.

Our quality assurance is something clients can verify, not just hear in a sales pitch. We use dimensional checks, hardness tests, and visual inspections from raw material up to final packing. Our work follows ISO 9001 and aligns with international guidelines like ASTM, DIN, FDA, and RoHS, and we draw from practices used in ISO 14001 and IATF 16949 environments. This focus on system-based quality is a main reason many firms call us their most trusted rubber manufacturer and trusted supplier.

Customization is also a core strength. We adjust sizes, shapes, colors, hardness levels, and rubber compounds so that each part fits exactly what the machine or structure needs. Our team works with EPDM, Neoprene, Silicone, Viton, Nitrile, natural rubber, and blended materials, and we support both simple parts and very detailed custom pieces. By sharing our experience early in the design stage, we help clients avoid errors that can appear later during installation or operation.

At the same time, we know cost and timing matter as much as quality. Our manufacturing facility can handle large runs while still giving careful attention to custom jobs, which keeps lead times realistic and deliveries on schedule. We focus on cost-efficient quality rubber products, so clients do not have to choose between price and performance. We also follow eco-friendly and more sustainable practices in our production, and our mission is clear: satisfy and go beyond expectations through responsive support, clear communication, and lasting partnerships across the Philippines.

Conclusion

Choosing a truly trusted rubber manufacturer is one of the most important decisions an industrial buyer can make. The right partner protects uptime, keeps people safe, and guards every project budget from hidden costs that come from poor quality parts.

At RK Rubber Enterprise Co., we combine strict quality control, wide customization, and a strong customer-focused approach to act as a trusted rubber manufacturer and trusted rubber supplier for many Philippine companies. We already support automotive, construction, marine, power, water, residential, and commercial projects across NCR, Visayas, and Mindanao, and we keep pushing Philippine rubber manufacturing toward global standards.

If you want a partner that will listen, share expertise, and respond fast when requirements change, we are ready to help. Reach out to us for a technical consultation, a custom quote, or to discuss any rubber requirement for your plant or project. Let us show you how the RK Rubber difference can support your success for the long run.

FAQs

What Industries Does RK Rubber Enterprise Co. Serve In The Philippines?

We serve a wide range of industrial rubber products across the country. Our clients include mechanical engineering firms, automotive manufacturers and OEM suppliers, marine and shipbuilding companies, and operators of industrial machinery. We also support construction, power generation, and water management projects, along with aerospace, agriculture, residential, and commercial developments. From NCR to Visayas and Mindanao, we work with both large industrial plants and highly specialized applications.

How Does RK Rubber Ensure Product Quality And Consistency?

We apply strict quality control at every stage of production. Our team performs dimensional checks, hardness tests, and visual inspections from incoming raw materials to finished products. We follow international standards such as ISO 9001 along with ASTM, DIN, FDA, and RoHS guidelines. We apply a zero-defect mindset and always look for ways to improve our processes. Our manufacturing facility supports this approach and helps us deliver reliable, long-lasting parts.

Can RK Rubber Create Custom Rubber Products To My Exact Specifications?

Yes, customization is one of our strongest points as a trusted rubber manufacturer. We can adjust sizes, shapes, colors, hardness levels, and material mixes across almost all product types. Our team works closely with you to understand the application, refine the drawings, and choose the right rubber compounds such as EPDM, Neoprene, Silicone, Viton, Nitrile, natural, synthetic, or blended options. We handle both simple shapes and very complex designs. You can contact us anytime to discuss your specific requirements.

What Makes RK Rubber Different From Other Rubber Suppliers In The Philippines?

Three things stand out for our clients:

We also follow eco-friendly production practices and work toward our vision of helping the Philippines grow as a major global exporter of rubber products. Our goal is to exceed expectations and build long-term, trust-based partnerships with every client we serve.

Bonding Rubber to Concrete: Adhesives and Prep Guide

in Rubber ProductWhen we talk about bonding rubber to concrete, most project teams first think about the rubber’s thickness, hardness, and color. The thin layer of adhesive underneath often feels like an afterthought, until a floor tile lifts, a water stopper leaks, or a machine pad starts to creep across the slab. That is when the real cost of a poor bond shows up in downtime, callbacks, and safety risks.

Across plants, building sites, and infrastructure works, a lot rides on how well bonding rubber to concrete is planned and executed. Expansion joints, water stoppers, anti‑vibration pads, rubber flooring, protective linings, and sealing systems only deliver their design performance when the adhesive matches both the rubber compound and the concrete condition. The wrong adhesive choice, or a rushed application, can turn a high‑quality rubber component into a weak link.

At RK Rubber Enterprise Co., we see this every week. Our EPDM door seals, preformed expansion joint fillers, water stoppers, linings, and anti‑vibration pads are engineered for weather resistance, chemical resistance, and long service life. Their full value appears only when bonding rubber to concrete is done with the right adhesive and correct surface preparation. In this article we walk through the main adhesive types, the surface preparation steps we insist on, and the best practices we recommend so that every rubber component bonded to concrete works as intended for many years.

Key Takeaways

Understanding Adhesive Types For Rubber-To-Concrete Bonding

Bonding rubber to concrete is not as simple as “glue it and forget it.” Rubber is flexible and often non‑porous, while concrete is rigid and porous. They move differently with load and temperature, so any adhesive between them has to cope with both stretching and gripping a rough mineral surface.

General construction adhesives are often not designed for this job. Water‑based VAE resin emulsions, for example, bond new concrete to old concrete very well but usually list rubber as an excluded material. To support reliable bonding rubber to concrete, we focus on three adhesive groups that handle this combination effectively when used correctly.

Synthetic Rubber Adhesives

Synthetic rubber adhesives use a blend of synthetic rubber and synthetic resin dissolved in a solvent. This mix gives a flexible bond line that moves with the rubber while still gripping the concrete surface firmly. That flexibility helps the adhesive survive vibration, impact, and temperature swings without cracking.

Key advantages include:

These adhesives work especially well for:

Commercial products in this category are widely available. At RK Rubber Enterprise Co., our role is to help clients pair these adhesives with the right rubber components and proper surface preparation, so the complete system performs as intended.

Contact Cement

Contact cement is a neoprene‑based adhesive that creates a very fast bond when the two coated surfaces touch. For bonding rubber to concrete over large areas, such as sheets of flooring of flooring or wall linings, this instant grab can save a lot of clamping time and temporary fixtures.

The application process is different from many glues:

Because of this, careful alignment planning is essential. There is almost no chance to reposition after contact, so installers often:

Contact cements give off strong vapors with volatile organic compounds, so good ventilation and proper protective equipment are non‑negotiable during use.

Two-Component Epoxies

Two‑component epoxies consist of a resin and a hardener that are mixed just before use. Once combined, they react chemically and cure into a very strong, rigid material. For bonding rubber to concrete in heavy‑duty settings with high loads or chemical exposure, this class often gives the highest margin of safety.

Typical benefits include:

The trade‑off is that epoxies demand more discipline:

A simple way to think about selection is:

Critical Surface Preparation For Maximum Bond Strength

From our experience, about eighty percent of success in bonding rubber to concrete comes from what happens before the adhesive can even be opened. Adhesives only stick to what they can actually touch, so any dust, oil, moisture, or weak concrete layer becomes a future failure plane.

For this reason, we build surface preparation into our recommendations for products like preformed expansion joint fillers and water stoppers. When our high‑grade rubber meets a well‑prepared slab, the combination can work for many years under traffic, movement, and weather. When preparation is skipped, even the best adhesive and rubber struggle to perform.

Preparing Concrete Surfaces

Concrete may look solid, but its surface often carries dust, laitance, oil stains, curing compounds, or old coatings. Effective preparation usually follows this sequence:

A slab prepared this way gives any rubber‑to‑concrete bond a far better chance of long service life.

Preparing Rubber Surfaces

Rubber parts arrive with their own set of surface issues. Mold release agents, talc, and light oxidation all reduce adhesion if left untouched.

A typical preparation sequence is:

Certain rubbers, such as EPDM or silicone, benefit from a primer approved by the adhesive manufacturer. This thin coating changes the surface energy of the rubber and builds a better chemical bridge to the adhesive.

At RK Rubber Enterprise Co., many of our door seals, water stoppers, anti‑vibration pads, and expansion materials use advanced compounds like EPDM, natural rubber, SBR, and neoprene. When we advise on bonding these to concrete, we always stress that good surface preparation protects their built‑in weather and chemical resistance by avoiding early debonding.

Application Best Practices And Safety Protocols