Bonding Rubber to Concrete: Adhesives and Prep Guide

When we talk about bonding rubber to concrete, most project teams first think about the rubber’s thickness, hardness, and color. The thin layer of adhesive underneath often feels like an afterthought, until a floor tile lifts, a water stopper leaks, or a machine pad starts to creep across the slab. That is when the real cost of a poor bond shows up in downtime, callbacks, and safety risks.

Across plants, building sites, and infrastructure works, a lot rides on how well bonding rubber to concrete is planned and executed. Expansion joints, water stoppers, anti‑vibration pads, rubber flooring, protective linings, and sealing systems only deliver their design performance when the adhesive matches both the rubber compound and the concrete condition. The wrong adhesive choice, or a rushed application, can turn a high‑quality rubber component into a weak link.

At RK Rubber Enterprise Co., we see this every week. Our EPDM door seals, preformed expansion joint fillers, water stoppers, linings, and anti‑vibration pads are engineered for weather resistance, chemical resistance, and long service life. Their full value appears only when bonding rubber to concrete is done with the right adhesive and correct surface preparation. In this article we walk through the main adhesive types, the surface preparation steps we insist on, and the best practices we recommend so that every rubber component bonded to concrete works as intended for many years.

As one maintenance supervisor told us, “We almost never lose the rubber part; we lose the bond line.”

Key Takeaways

- Three adhesive families cover most needs for bonding rubber to concrete: synthetic rubber adhesives, contact cements, and two‑component epoxies. Each has clear strengths and limits. Matching these to project conditions prevents early failures and repeated rework.

- Good surface preparation makes or breaks a rubber‑to‑concrete bond. Cleaning, drying, and mechanical abrasion on both concrete and rubber give the adhesive a sound surface. This preparation should be treated as part of design, not a quick step before installation.

- Contact cements give instant grip for bonding rubber to concrete on large areas. They also allow almost no repositioning once surfaces touch, so layout and alignment planning become very important. Epoxies give higher strength but need longer curing and tighter control of mixing.

- Temperature range must match the real environment where bonding rubber to concrete is done. Adhesives have specific working and service temperature limits, and ignoring them can lead to hardening, softening, or peeling. Checking this data early prevents surprises on site.

- At RK Rubber Enterprise Co., we support projects beyond supplying rubber parts. We share surface preparation checks, adhesive selection pointers, and step‑by‑step guidance so bonding rubber to concrete with our products is consistent, safe, and long lasting.

Understanding Adhesive Types For Rubber-To-Concrete Bonding

Bonding rubber to concrete is not as simple as “glue it and forget it.” Rubber is flexible and often non‑porous, while concrete is rigid and porous. They move differently with load and temperature, so any adhesive between them has to cope with both stretching and gripping a rough mineral surface.

General construction adhesives are often not designed for this job. Water‑based VAE resin emulsions, for example, bond new concrete to old concrete very well but usually list rubber as an excluded material. To support reliable bonding rubber to concrete, we focus on three adhesive groups that handle this combination effectively when used correctly.

Synthetic Rubber Adhesives

Synthetic rubber adhesives use a blend of synthetic rubber and synthetic resin dissolved in a solvent. This mix gives a flexible bond line that moves with the rubber while still gripping the concrete surface firmly. That flexibility helps the adhesive survive vibration, impact, and temperature swings without cracking.

Key advantages include:

- Wide material compatibility – A single product can bond natural rubber, synthetic rubber, concrete, metal, plastics, and wood, which is very helpful on mixed‑material projects.

- Broad temperature resistance – Often covering roughly −40 °C up to about 80 °C, suitable for many conditions in the Philippines and similar climates.

- Good fatigue behavior – The flexible bond line holds up under repeated movement, which is common in machinery mounts and expansion assemblies.

These adhesives work especially well for:

- Industrial rubber flooring

- Protective linings inside concrete tanks

- Vibration‑control pads on machinery bases

- Architectural rubber details fixed to slabs or walls

Commercial products in this category are widely available. At RK Rubber Enterprise Co., our role is to help clients pair these adhesives with the right rubber components and proper surface preparation, so the complete system performs as intended.

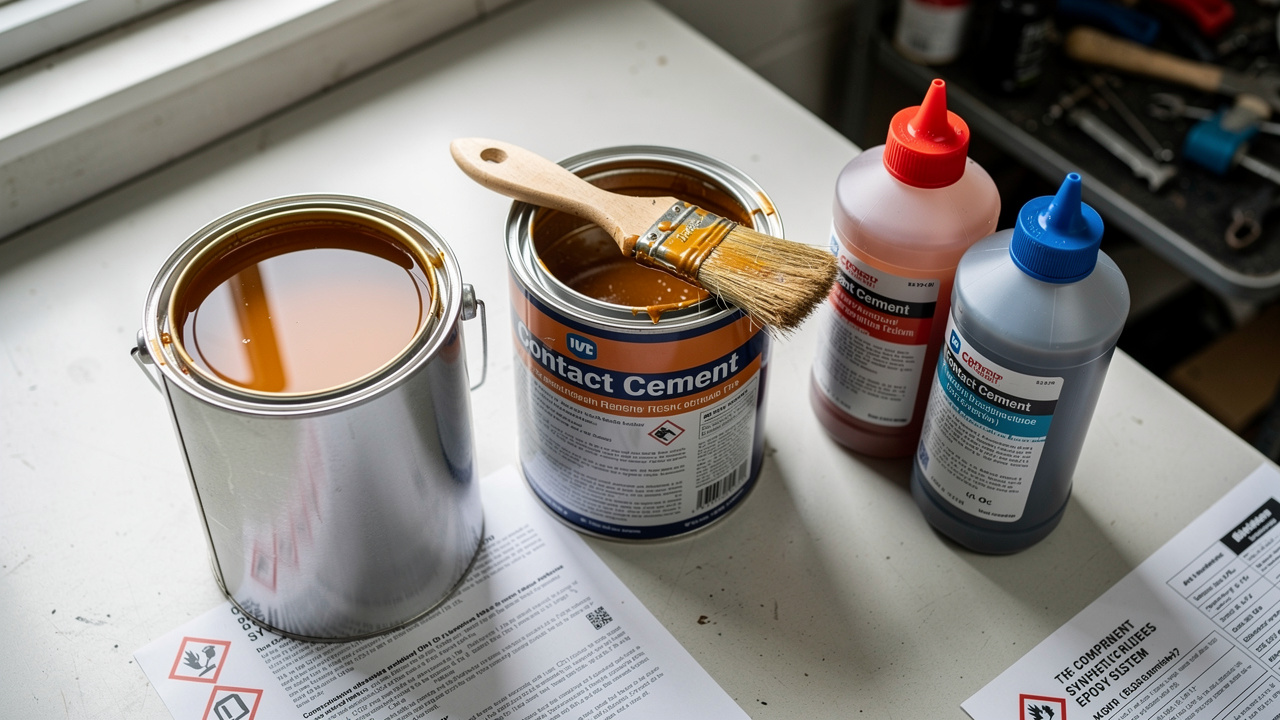

Contact Cement

Contact cement is a neoprene‑based adhesive that creates a very fast bond when the two coated surfaces touch. For bonding rubber to concrete over large areas, such as sheets of flooring of flooring or wall linings, this instant grab can save a lot of clamping time and temporary fixtures.

The application process is different from many glues:

- A thin, even layer is applied to both the prepared concrete and the back of the rubber.

- The installer waits until the solvent has flashed off and the film feels dry yet tacky.

- When the two sides meet under firm pressure, the bond forms almost at once.

Because of this, careful alignment planning is essential. There is almost no chance to reposition after contact, so installers often:

- Use slip sheets and pull them out gradually.

- Work from one edge and roll across the surface to avoid trapped air.

- Mark reference lines on the slab before adhesive work starts.

Contact cements give off strong vapors with volatile organic compounds, so good ventilation and proper protective equipment are non‑negotiable during use.

Two-Component Epoxies

Two‑component epoxies consist of a resin and a hardener that are mixed just before use. Once combined, they react chemically and cure into a very strong, rigid material. For bonding rubber to concrete in heavy‑duty settings with high loads or chemical exposure, this class often gives the highest margin of safety.

Typical benefits include:

- Very high bond strength, often greater than the tensile strength of the concrete itself.

- Strong resistance to water, fuels, oils, and many industrial chemicals.

- Useful gap‑filling ability, helpful when the concrete is slightly uneven or pitted.

- Specialized grades that can cure in damp or wet conditions, valuable in water treatment plants or marine projects.

The trade‑off is that epoxies demand more discipline:

- There is a limited pot life after mixing.

- Full cure can take one to three days before design strength is reached.

- Surface preparation has to be very thorough.

- Project teams must protect the fresh bond from movement and heavy loading while it cures.

Adhesives specialists often remind installers: “Epoxy is only as strong as the surface you stick it to.”

A simple way to think about selection is:

| Adhesive Type | Best For | Less Suitable When |

|---|---|---|

| Synthetic Rubber Adhesive | General‑purpose bonding rubber to concrete and metals | Very high chemical or temperature exposure |

| Contact Cement | Large sheet goods, flooring, and wall linings | Situations needing repositioning after placement |

| Two‑Component Epoxy | Heavy loads, wet areas, and chemical exposure | Applications needing a flexible bond line |

Critical Surface Preparation For Maximum Bond Strength

From our experience, about eighty percent of success in bonding rubber to concrete comes from what happens before the adhesive can even be opened. Adhesives only stick to what they can actually touch, so any dust, oil, moisture, or weak concrete layer becomes a future failure plane.

For this reason, we build surface preparation into our recommendations for products like preformed expansion joint fillers and water stoppers. When our high‑grade rubber meets a well‑prepared slab, the combination can work for many years under traffic, movement, and weather. When preparation is skipped, even the best adhesive and rubber struggle to perform.

A common saying among flooring installers is, “Adhesives rarely fail—dirty substrates do.”

Preparing Concrete Surfaces

Concrete may look solid, but its surface often carries dust, laitance, oil stains, curing compounds, or old coatings. Effective preparation usually follows this sequence:

- Initial cleaning

- Sweep or vacuum to remove loose particles.

- Use degreasers where oil or grease is visible.

- Pressure wash if compatible with the project, then allow the slab to dry.

- Check moisture levels

- Many adhesives require a dry slab, not just a dry surface.

- Simple field checks, such as taping clear plastic over the slab and looking for condensation, can reveal ongoing moisture emission.

- New concrete usually needs at least twenty‑eight days before adhesive work starts, depending on mix and curing conditions.

- Create a surface profile

- Methods such as shot blasting, diamond grinding, or scarifying remove the weak top layer and create a roughened texture that gives the adhesive a mechanical key.

- The goal is a clean, sound, and evenly textured surface without glossy patches.

- Repair defects and remove dust

- Repair cracks, spalls, and holes with suitable mortars or epoxy fillers.

- Re‑grind repaired zones if necessary to bring them flush.

- Finish with an industrial vacuum or oil‑free compressed air to clear remaining dust so the adhesive can wet the concrete fully.

A slab prepared this way gives any rubber‑to‑concrete bond a far better chance of long service life.

Preparing Rubber Surfaces

Rubber parts arrive with their own set of surface issues. Mold release agents, talc, and light oxidation all reduce adhesion if left untouched.

A typical preparation sequence is:

- Solvent cleaning – Wipe the bonding face with an appropriate solvent such as acetone, MEK, or isopropyl alcohol, often using a two‑rag method so that dissolved contaminants are lifted away rather than smeared.

- Light mechanical abrasion – For most rubber compounds used when bonding rubber to concrete, light sanding with medium‑grit paper removes the glossy skin and exposes a fresh, slightly rough surface. The aim is a uniform, dull appearance without deep scratches that could act as stress raisers.

- Final wipe – After sanding, another careful solvent wipe removes all dust and loose particles.

Certain rubbers, such as EPDM or silicone, benefit from a primer approved by the adhesive manufacturer. This thin coating changes the surface energy of the rubber and builds a better chemical bridge to the adhesive.

At RK Rubber Enterprise Co., many of our door seals, water stoppers, anti‑vibration pads, and expansion materials use advanced compounds like EPDM, natural rubber, SBR, and neoprene. When we advise on bonding these to concrete, we always stress that good surface preparation protects their built‑in weather and chemical resistance by avoiding early debonding.

Application Best Practices And Safety Protocols

Once both surfaces are prepared, technique takes center stage. The same adhesive can perform very differently depending on how it is mixed, applied, pressed, and cured. Our team often supports engineers and contractors with simple checklists so bonding rubber to concrete becomes a controlled process rather than a guess.

At the same time, many of these adhesives involve solvents, reactive resins, and strong fumes. Safety for installers and nearby staff is a basic requirement. We always pair technical advice with clear reminders on ventilation, protective gear, and fire prevention.

Safety Requirements

- Ventilation

- Work areas for bonding rubber to concrete need strong airflow.

- Open doors and windows where possible and use fans or extraction systems in enclosed spaces.

- Good airflow helps keep vapors below harmful levels and improves drying of solvent‑based products.

- Personal protective equipment

- Every installer should wear chemical‑resistant gloves, safety goggles or a face shield, and suitable work clothing.

- When fumes are present, a respirator with organic vapor cartridges protects the lungs.

- Brief workers on correct use of PPE before work starts.

- Fire safety

- Solvent‑based adhesives can be highly flammable.

- Keep open flames, welding sparks, smoking, and unprotected electrical tools away from the area.

- Place appropriate fire extinguishers for flammable liquids nearby, and close containers as soon as each batch is applied.

- Storage and disposal

- Store adhesives in cool, dry locations within the temperature limits on the label and never under direct sun.

- Keep lids tightly closed when not in use to avoid skinning and vapor build‑up.

- Handle unused or expired material, solvent waste, and contaminated rags under local regulations, and never pour them into drains or mix with regular trash.

Step-By-Step Application Process

When installing RK Rubber products on concrete, a clear, repeatable process helps keep results consistent:

- Using contact cement

- Apply a thin, even coat on both the prepared concrete and the rubber. Rollers or notched trowels help control thickness over larger areas, while brushes can handle small or detailed zones.

- Wait until the film is dry to the touch yet still tacky before bringing the two sides together with careful alignment.

- Start pressing from one edge and work across the area to avoid trapping air. A heavy floor roller works well on flat flooring, while a hand roller or padded block helps with vertical or shaped surfaces.

- Once contact is made, there is almost no chance for correction, so plan dry layouts and trial positioning in advance.

- Using synthetic rubber adhesives or epoxies

- Most synthetic rubber adhesives and epoxies are applied to the concrete only, although some systems call for priming the rubber.

- Two‑part epoxies must be mixed in the exact ratio and within their pot life, using slow, thorough mixing that scrapes container sides and base.

- Spread the adhesive with a notched trowel to the recommended thickness.

- Place the rubber within the open time, with gentle sliding or pressing to achieve full contact. Use weights, clamps, or temporary fasteners if specified.

- Curing and clean‑up

- Curing is the quiet stage that often gets rushed in bonding rubber to concrete. Follow the manufacturer’s timing for initial set and full cure, and keep temperature within the recommended band, usually near normal room conditions.

- Keep heavy traffic, machinery loads, or chemical wash‑downs away until full cure so the bond can reach its designed strength without early stress.

- Wipe away excess adhesive while still soft using the recommended solvent. Cured squeeze‑out can be carefully trimmed once the bond has fully hardened.

How RK Rubber Products Excel In Concrete-Bonded Applications

At RK Rubber Enterprise Co., our main business is manufacturing rubber components, not producing adhesives. Use of waste rubber in construction applications has grown significantly, and we design every profile, pad, and seal with a clear view of how it will behave once bonded to concrete, steel, or other substrates on site. Even so, we design every profile, pad, and seal with a clear view of how it will behave once bonded to concrete, steel, or other substrates on site. That means paying close attention to flexibility, compression set, chemical resistance, and long‑term aging.

Many of our products are intended for bonding rubber to concrete in demanding roles:

- Preformed expansion joint fillers are supplied with clear notes on primer and adhesive use so that joints can move without losing support.

- Rubber water stoppers in EPDM or neoprene rely on a stable bond to concrete to keep joints watertight while accommodating movement.

- Anti‑vibration pads and customized rubber footings need firm anchoring to slabs so they can isolate machinery effectively and reduce noise.

- EPDM door seals depend on consistent adhesion along thresholds and frames to keep out water, dust, and drafts.

We choose and compound materials for strong resistance to resistance to weather, UV, oils, and many industrial chemicals. Our ability to customize shapes and hardness helps reduce stress concentrations at edges, which also supports adhesive performance. With manufacturing under international standards such as ISO 9001 and relevant ASTM or DIN references, we aim to give project teams confidence that once bonding rubber to concrete is handled correctly, the rubber side of the system will perform reliably for many years.

Conclusion

Strong, reliable bonding rubber to concrete rests on three linked pillars. First, the adhesive type must suit the task, whether that means flexible synthetic rubber adhesive, fast‑grip contact cement, or high‑strength epoxy for heavy‑duty conditions. Second, both concrete and rubber need careful preparation so the adhesive meets clean, sound, and profiled surfaces. Third, application and curing must follow clear steps for mixing, spreading, pressing, and waiting before full loading.

When these points come together, the long‑term performance and life‑cycle cost of floors, joints, linings, and machine bases improve sharply. At RK Rubber Enterprise Co., we supply rubber components with built‑in strength, weather resistance, and chemical resistance, and we also share the practical guidance that helps installations succeed. For projects in industrial plants, buildings, infrastructure, or residential developments that involve bonding rubber to concrete, our team is ready to discuss product options, review site conditions, and support detailed installation planning.

FAQs

Question 1: What Is The Most Important Factor In Achieving A Strong Rubber-To-Concrete Bond?

From our field experience, surface preparation is the single most important factor. Both concrete and rubber must be clean, dry, and mechanically abraded so the adhesive touches solid material. Even premium products for bonding rubber to concrete fail early when applied over dust, oil, moisture, or glossy factory skins.

Question 2: Can I Use Standard Construction Adhesives For Bonding Rubber To Concrete?

General construction adhesives are often not designed for elastomeric materials. Water‑based VAE emulsions, for example, are good for bonding concrete to concrete but usually exclude rubber on their data sheets. We recommend choosing synthetic rubber adhesives, contact cements, or two‑component epoxies that are clearly formulated for bonding rubber to concrete so the bond does not peel or soften under load.

Question 3: How Long Should I Wait Before Subjecting The Bonded Rubber To Heavy Loads Or Traffic?

Handling strength from contact cement often appears as soon as the rubber is pressed into place, but full cure still benefits from about twenty‑four hours. Epoxies can need from one to three days to reach full mechanical properties, depending on the brand and temperature. Applying heavy traffic or high loads too early on bonding rubber to concrete can cause micro‑movement, which may lead to long‑term debonding.

Question 4: What Should I Do If My Concrete Surface Is Uneven Or Has Cracks?

We always advise repairing defects before bonding rubber to concrete:

- Hairline cracks may accept flexible fillers.

- Wider or structural cracks often need epoxy injection or engineering review.

- Spalls and holes should be cut back to sound concrete and patched with suitable repair mortar.

After repairs, re‑profile the surface if needed, then consider a two‑component epoxy adhesive to help bridge minor remaining unevenness during the bonding step.

Question 5: Does RK Rubber Enterprise Co. Provide Adhesive Recommendations For Your Rubber Products?

We focus on manufacturing high‑quality rubber components and do not produce adhesive brands ourselves. However, our installation guides—especially for items like preformed expansion joint fillers and water stoppers—describe surface preparation, priming steps, and general adhesive types that suit bonding rubber to concrete. Our technical and sales teams work with project engineers to match professional‑grade adhesives to our rubber compounds so that the complete system performs as intended.

Leave a Reply

Want to join the discussion?Feel free to contribute!