Elastomeric Bearing Pad

Our elastomeric bearing pad is made from high-quality rubber materials such as neoprene based on the International Construction Measurement Standards Coalition (ICMSC). The elastomeric bearing pad is widely used in bridges, low to high-rise buildings, dams, and other related building constructions. A bearing pad’s primary function is to lessen the vibration of structures because it minimizes the movement caused by environmental changes like the weather, traffic density, and other factors that may affect the superstructures’ substantial activity. Having a high-quality elastomeric bearing pad is a must when building a foundation of any structure because it supports components by absorbing vertical and horizontal loads.

The elastomeric bearing pad offers a number of benefits in bridge construction, including:

- Reduced noise and vibration

- Elimination of metal-to-metal contact

- Extended lifespan of the bridge

- Reduced maintenance costs

If you’re looking for a way to improve your bridge construction project, consider using elastomeric bearing pads. They offer a number of benefits that can make your project run more smoothly and efficiently.

Years of Service Elastomeric Bearing Pad

Elastomeric bearing pads are engineered to serve a required life of a structure. It can operate for several years under exposure to chemicals and extreme weather conditions without deterioration. Many experts agree that the elastomeric bearing pad will offer a very long life service with less maintenance by using high-grade materials than other types of bearings that were poorly constructed. According to some engineers, additional material testing is needed because aging and extreme weather conditions still contribute to the elastomeric bearing pad service, ensuring its excellent resistance and durability.

Kinds of Bearing Pads

- Elastomeric Bearing Pad is a type of pad used to support heavy loads. They have several properties that make them well suited for this application. These properties include their ability to deform under load, their resistance to wear, and their ability to dampen vibrations. Other bearing pads are steel/laminated, reinforced with fiberglass, and the plain type.

- Disk Bearing Pad – are a type of bearing used in bridge construction. They are made of several metal disks placed between the bridge deck and the support beams. This helps distribute the bridge’s weight evenly and prevents damage to the bridge deck. Disk bearing pads are also used in other construction applications, such as building foundations. It is very flexible because it allows a rotational movement from a vertical load without sacrificing large deformations.

- Sliding Bearings – A sliding elastomeric bearing pad, also referred to as an S-pad, is a device that is used to reduce friction between two surfaces. It is made of an elastomeric material, such as rubber or silicone, which allows it to conform to the surface of the object it is touching. This creates a seal that helps to reduce the amount of friction between the two surfaces. This bearing pad has metal plates that slide to make a transitional movement. It cannot be used in a span below 16m, and it requires a lubricant to remove its generated friction.

- Curved Bearings – are made of synthetic rubber, designed to absorb the impact of traffic loading on a bridge. The curved design of this bearing pad distributes the load more evenly over the surface of the bridge deck, which reduces wear and tear on the bridge. It’s less likely to cause noise and vibration than standard steel bearing pads. This bearing pad has two options: spherical and cylindrical. The spherical bearing can only use for rotational movement, while the cylindrical bearing pad can operate in both translational and rotational movement of the structure.

- Roller Bearing Pad is used to reduce noise and vibration. They are made of soft elastomeric material and placed between the bearing and the mounting surface. It is used in equipment subject to harsh conditions, such as high temperatures or constant vibration. It can be installed in a steel bridge and reinforced concrete structures, and there are two settings for this roller bearing: the multiple and single roller bearing. The multiple rollers bearing pads are composed of various rollers installed between the plates, while the single roller has only one, of course.

- Pin and Rocker Bearings – is a device that helps distribute weight across a surface evenly. It comprises two parts: the pin, which is inserted into the surface, and the rocker, which rests on top of the pin. The rocker helps to distribute the weight of whatever is being supported evenly across the surface of the pin. This can help prevent damage to delicate surfaces or make it easier to move heavy objects around. Commonly deployed in steel reinforce bridges that can accommodate both rotational and transitional movement. This kind of bearing can degrade its performance over time and be prone to corrosion; it needs proper and regular maintenance to utilize its full potential.

Advantage & Disadvantages

Elastomeric bearing pads for bridges have a lot of advantages, but there are also some disadvantages in using them. One of the benefits is that they are very durable and can last a long time. They are also resistant to weathering and can withstand extreme temperatures. Another advantage is that they are very easy to install and don’t require much maintenance. However, one downside is that they can be quite expensive. They also don’t perform as well in cold weather conditions.

In conclusion, installing an elastomeric pad is essential in order to protect the bridge from damage. If this damage is not prevented, it could lead to a collapse of the bridge. So, it is a crucial step that must be taken to ensure drivers’ and passengers’ safety.

Watch the videos below to see how the elastomeric bearing pad is used in bridge construction.

Based on the video, pads are being placed between the bridge and bridge pier as vertical support. The goal is to disseminate the horizontal and vertical loads of the bridge to the pier, so it can create a movement caused by the environment without collapsing. Source: Youtube

In this video, it will show how the bearing pad is essential on seismic retrofitting or creating a foundation of bridges and building. Every superstructure may affect displacements or force of shears caused by seismic, and it should have a high-quality bearing pad, whether it is a plain or laminated bearing pad to make it stronger while allowing it to move. Source: Youtube

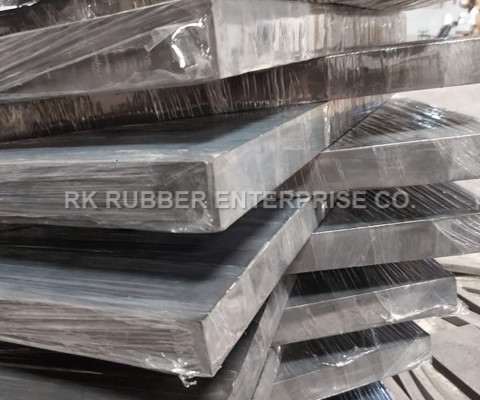

Elastomeric Bearing Pad Quick Details

Application Type: Civil Engineering Projects

Material: Neoprene, Natural Rubber, Steel

Color: Plain black

Variants/ Type: Dimensions will be base on the client’s specifications; Laminated elastomeric bearings, neoprene bridge bearings, seismic isolators, and pads.

Purpose: The support system of the bridge allows some irregular movements despite heavy load to avoid bridge collapse.

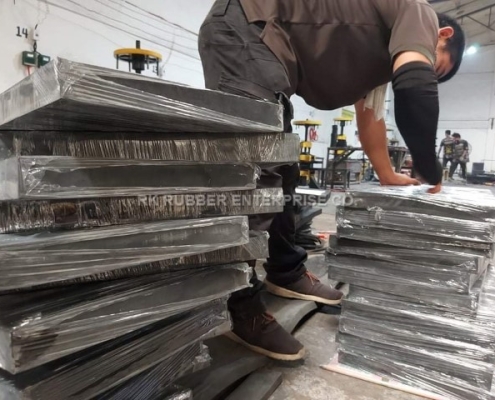

Below are some of the actual products and applications.