Viton gaskets vs EPDM: high-performance sealing guide

A single gasket can shut down an entire plant. We have seen it happen in fuel depots, boiler rooms, and chemical lines across the Philippines. One small ring of rubber hardens, swells, or cracks, and the result is leaks, unplanned stoppage, safety risk, and a lot of stress for everyone from maintenance to management.

As one maintenance supervisor told us, “A five‑peso gasket can stop a five‑million‑peso line if you pick the wrong material.”

This is why the choice between EPDM and Viton gaskets matters far more than it seems on paper. Both belong to the same broad family of elastomers, yet they behave very differently once fuels, acids, steam, or high heat enter the picture. EPDM often looks cheaper and “good enough” until it meets petroleum products or higher temperatures and fails sooner than planned.

For many plants, contractors, and OEMs, the key question is simple: When is EPDM fine, and when do conditions justify an upgrade to Viton for high‑performance sealing? In this guide, we compare the two materials where it matters most: chemical resistance, temperature limits, cost over time, and field suitability.

At RK Rubber Enterprise Co., we work with Philippine industrial users every day on this decision. The aim is to match gasket material to real service conditions with confidence, know when Viton is a smart investment, and know when EPDM still delivers strong value.

Key Takeaways

-

Viton gaskets excel where fuel, oil, aggressive solvents, or concentrated chemicals are present, especially near 200°C, making them ideal for oil and gas, chemical processing, mining, and fuel systems.

-

EPDM gaskets are strong performers in water‑based and outdoor applications with weather, ozone, and UV exposure, and typically handle up to about 150°C at a lower cost.

-

Upgrading from EPDM to Viton makes sense when systems handle fuels, petroleum oils, strong acids, harsh solvents, or any mix of those at raised temperature, particularly in safety‑critical or hard‑to‑reach lines.

-

Good material choice balances chemical compatibility, temperature, pressure, plant standards, and long‑term cost. RK Rubber Enterprise Co. helps clients weigh these factors using real operating data, not guesswork.

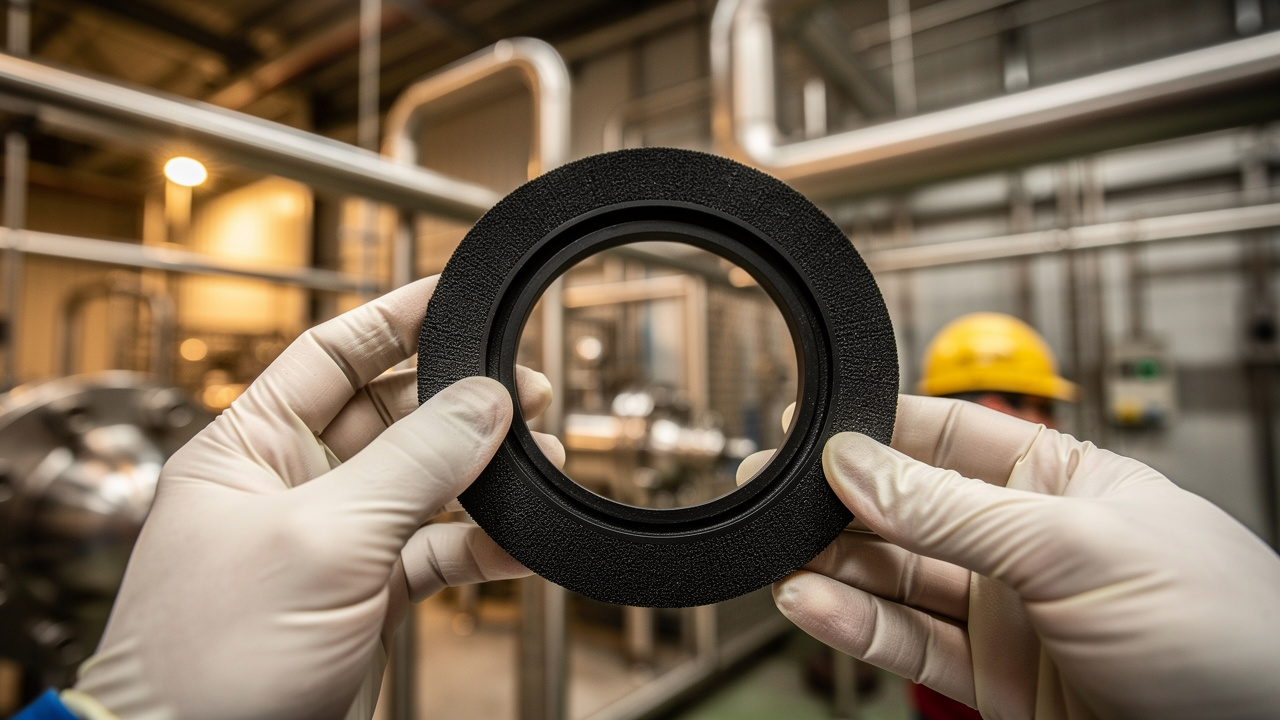

What Are Viton Gaskets and Why They Matter for High-Performance Sealing

When we talk about Viton gaskets, we mean gaskets made from Viton, a fluoroelastomer (FKM) synthetic rubber. Its high fluorine content gives it strong resistance to fuels, oils, and many aggressive chemicals, even at raised temperature.

In practice, Viton provides a tight, long‑lasting seal in places where standard rubber would soften, swell, or crack, with performance verification of elastomer materials confirming its superior stability under stress. Gaskets sit clamped between flanges or covers for years while hot fuels, solvents, or mixed process fluids pass by. Viton resists this combination of thermal and chemical stress much better than general‑purpose elastomers.

Because of this, Viton is treated as a premium material. It appears in:

-

Refineries, depots, and petrochemical plants (valves, pump seals, manways)

-

Automotive and aerospace fuel systems and transmission seals

-

Hydraulic systems with aggressive fluids and higher temperatures

RK Rubber Enterprise Co. supports these needs with Viton O‑rings and Viton gaskets rated for roughly -20°C to about 200°C, plus PTFE‑encapsulated variants for tougher chemical service. What our clients value most is seal integrity over time: Viton resists compression set and maintains elasticity against fuels, acids, bases, hydraulic fluids, and many solvents where EPDM or Nitrile would struggle.

Understanding EPDM Gaskets: The Versatile Workhorse of Industrial Sealing

EPDM, short for Ethylene Propylene Diene Monomer, is one of the most widely used synthetic rubbers in sealing work. EPDM gaskets resist weathering, ozone, and sunlight very well, staying flexible over a broad temperature range and offering a practical, cost‑friendly option for many projects.

Thanks to its saturated backbone, EPDM stays elastic instead of cracking when left outdoors for years. Typical gasket‑grade EPDM handles roughly -50°C up to about 150°C, which covers most water, HVAC, and non‑fuel duties in buildings and plants.

Chemically, EPDM works very well with:

-

Water, hot water, and many steam applications

-

Glycol‑based fluids and many alcohols

-

Mild acids and alkalis

However, it reacts badly with petroleum oils, fuels, and many hydrocarbon solvents, tending to swell and lose sealing force. That is why EPDM should not be used in fuel systems or oil lines.

Common uses include automotive door and window seals, HVAC and water line gaskets, and marine hatch seals. RK Rubber Enterprise Co. supplies EPDM gaskets and rubber tubing to many sectors across the Philippines, often as the best mix of price, durability, and service life where petroleum products are not present.

Critical Performance Differences: Viton Vs. EPDM Chemical Resistance

When engineers ask whether they should move from EPDM to Viton gaskets, chemical resistance is usually the first topic. Each material handles certain media well and fails badly with others, so matching the material to the actual fluid list is essential.

Viton offers broad chemical resistance, especially for hydrocarbons and strong process fluids. It handles petrol, diesel, jet fuel, mineral oils, synthetic lubricants, many hydraulic oils, and a wide range of hydrocarbon solvents. It also resists many acids and bases that quickly damage general‑purpose rubbers.

EPDM sits nearly on the other side of the chart. It performs very well with water, hot water, steam, glycols, many alcohols, and dilute acids and alkalis, which explains its popularity in municipal water and many cleaning lines. It fails, however, in true petroleum oils, fuels, and strong hydrocarbon solvents.

Use the table below as a quick guide:

|

Fluid Family |

Viton Gaskets |

EPDM Gaskets |

|---|---|---|

|

Fuels and petroleum oils |

Very suitable |

Not suitable |

|

Water, hot water, and steam |

Suitable |

Very suitable |

|

Many acids and bases |

Often suitable |

Often suitable at low level |

|

Alcohols and many glycols |

Often suitable |

Very suitable |

|

Many hydrocarbon solvents |

Often suitable |

Not suitable |

There are always exceptions, so we ask for exact product names or safety data sheets, then check compatibility before recommending Viton gaskets or any other material. In general, fuel system gaskets, oil line seals, and many petrochemical joints favor Viton, while hot‑water systems and many HVAC lines are strong candidates for EPDM.

Temperature Performance: When Viton’s Heat Resistance Becomes Essential

Temperature is the second major factor in the Viton versus EPDM choice. EPDM gaskets usually work well from about -50°C to roughly 150°C in continuous service. Viton typically covers about -20°C up to around 200°C, with short peaks above that. The extra margin at the high end often decides whether an upgrade is needed.

Heat does more than harden rubber; it also increases compression set—a gasket’s tendency to stay flattened and lose sealing force. Viton maintains a low compression set even near its upper temperature limit, while EPDM loses spring more quickly in that region.

This matters in:

-

Engine bays and fuel systems with hot exhaust parts nearby

-

Chemical plants and refineries with hot acids or solvent streams

-

Sterilization or cleaning systems using high heat and aggressive media

Because higher temperature also accelerates chemical attack, a medium that seems mild at room temperature can become much more damaging at 150–200°C. That is where Viton gaskets provide clear value, extending service life and cutting unplanned gasket changeouts.

Cost Vs. Performance: Making the Business Case for Upgrading to Viton

Viton compounds cost more to produce, so Viton gaskets often run three to five times the unit price of similar EPDM parts. Looking only at the purchase price can make Viton seem hard to justify.

We encourage clients to think in terms of total cost of ownership instead:

-

How long does each gasket last in real service?

-

How difficult is it to access and replace?

-

What is the cost of downtime and lost production?

-

What are the safety or environmental risks if it leaks?

For water lines, HVAC flanges, and outdoor weather seals, EPDM usually offers better value: it is affordable, easy to source, and reliable in moderate conditions.

“The cheapest gasket is rarely the least expensive option once you factor in downtime and labor.” — Senior maintenance planner, process plant client

Consider a line where an EPDM gasket lasts six months before swelling and leaking, but a Viton gasket in the same spot runs three years. Once labor, shutdown, and potential clean‑up are added, the higher‑priced Viton part often works out cheaper over the life of the asset and reduces emergency work.

Application Guide: When to Choose EPDM Vs. When to Upgrade to Viton

Many engineers and buyers want simple rules of thumb. Charts are helpful, but a quick mental checklist is often just as valuable.

Choose EPDM gaskets when:

-

The system is mainly water‑based (municipal water, hot water loops, many steam or HVAC lines).

-

The primary challenges are weather, ozone, and UV (window seals, door gaskets, façade and roof joints, marine hatch seals).

-

Temperatures stay at or below about 150°C and no fuels or oils are present.

Upgrade to Viton gaskets when:

-

The media includes fuels, petroleum oils, or gas streams with aggressive components.

-

Strong acids, harsh solvents, or explosive gases are part of the process.

-

Continuous temperature is above about 150°C, especially with chemicals in the mix.

-

The joint is safety‑critical, hard to reach, or tied to very expensive production equipment.

RK Rubber Enterprise Co. supports these decisions with EPDM and Viton in standard and custom profiles (including W‑type, J‑type, and special shapes), so clients do not have to compromise gasket geometry to gain better material performance.

Material Selection Best Practices: How RK Rubber Enterprise Co. Ensures Optimal Seal Performance

For us, choosing between EPDM and Viton gaskets is never just a quick yes or no. Real systems involve multiple fluids, cleaning cycles, pressure changes, movement, and local regulations.

Our process typically includes:

-

Application assessment

We clarify operating and peak temperatures, pressure range, joint type (static or moving), and thermal or pressure cycling. We also list every fluid that may contact the gasket, including cleaning agents. -

Material matching

Using compatibility data and field experience, we compare the duty against EPDM, Viton, and other elastomers. For food, beverage, and pharmaceutical work, we also consider hygiene and documentation requirements, along with local availability. -

Validation and testing

For severe applications, we can arrange tests that simulate years of service using heat, pressure, and chemical exposure, and then check hardness change, volume resistivity of Viton and other properties, and compression set. -

Installation and maintenance support

We assist with correct gasket sizing, bolt loading, and compression guidelines, then help define realistic inspection and replacement intervals to avoid surprise leaks.

By following this structured approach, RK Rubber Enterprise Co. offers more than rubber parts. We provide material selection support and practical advice that link design intent with field reality, so seals perform as expected on both technical and business terms.

Conclusion

Gasket material choice has a direct impact on safety, uptime, and long‑term cost. A seal that does not match its environment will swell, crack, or harden early, and the result is leaks, clean‑up work, and lost production.

EPDM remains an excellent choice for many Philippine applications: water‑based systems, outdoor joints exposed to sun and rain, HVAC ducting, chilled‑water loops, and many marine duties. In these roles, EPDM gaskets offer long life at a friendly price.

Once fuels, oils, aggressive chemicals, or sustained high temperature enter the picture, it is time to consider Viton gaskets. Their resistance to hydrocarbon media and many strong chemicals, combined with stable behavior near 200°C, makes them a safer and more predictable option, especially in safety‑critical or hard‑to‑reach locations.

We encourage plant managers, engineers, and contractors to think beyond unit price and look at total cost and risk. RK Rubber Enterprise Co. is ready to help—from material selection and custom design through installation guidance—so that small sealing parts support safe, steady operation for many years.

FAQs

Question 1: What Is the Main Difference Between Viton and EPDM Gaskets?

Viton gaskets are fluoroelastomer parts designed for fuels, oils, many aggressive chemicals, and temperatures up to about 200°C. EPDM gaskets work best with water, steam, many alcohols, and outdoor exposure, usually up to around 150°C, but they are not suitable for petroleum products.

Question 2: Can I Use EPDM Gaskets in Fuel Systems or With Petroleum Products?

No. EPDM swells and loses strength in contact with petrol, diesel, many oils, and strong hydrocarbon solvents, which can lead to leaks and fire risk. For fuel or oil service, we recommend Viton gaskets or other elastomers rated for hydrocarbons, selected with RK Rubber Enterprise Co.’s guidance.

Question 3: How Long Do Viton Gaskets Typically Last Compared to EPDM Gaskets?

Service life depends on temperature, pressure, media, and movement. In suitable duties, Viton gaskets often run for several years thanks to strong resistance to heat and chemicals. EPDM can also last years in water and outdoor roles, but fails quickly if misapplied in oils or fuels.

Question 4: Is Viton Suitable for Food-Grade or Pharmaceutical Applications?

Certain Viton grades can meet food‑contact and pharmaceutical requirements, but not all compounds are suitable. For these sectors, RK Rubber Enterprise Co. matches Viton gaskets or approved EPDM grades to the process fluids, cleaning methods, and relevant standards.

Question 5: How Do I Know If My Application Requires an Upgrade From EPDM to Viton?

Warning signs include: contact with fuels, petroleum oils, strong acids, harsh solvents, or mixed chemical streams; continuous temperature above about 150°C; repeated EPDM failures or swelling; and duties that are safety‑critical or hard to access. In these cases, our engineers can review your data and advise whether Viton gaskets are the better choice.

Leave a Reply

Want to join the discussion?Feel free to contribute!