Industrial Flood Seals for Reliable Warehouse Protection

Introduction

The first time we watched a warehouse floor vanish under brown floodwater, what shocked us was not the depth but the speed. In minutes, pallets, cartons, and machinery went from safe to scrap. Since then, we have treated industrial flood seals as seriously as any forklift or conveyor on site.

Across the Philippines, stronger typhoons, monsoon rains, and poor drainage keep putting warehouses at risk, with flood damage and infrastructure vulnerability becoming increasingly documented concerns. Once water reaches a loading dock or roll-up door, losses escalate fast: damaged inventory and racking, corroded equipment, long shutdowns, and safety issues for staff. Insurance may pay for part of the damage, but it does not repay lost production days or shaken client trust.

Heavy-duty rubber seals sit at the heart of any practical flood barrier. Steel and concrete carry the load, yet it is the rubber that closes the last few millimeters where water loves to sneak through. For each project we focus on door seals, water stoppers, and gate seals that can handle high water pressure, building movement, and harsh Philippine weather.

At RK Rubber Enterprise Co., we do more than manufacture rubber parts. We help clients avoid design mistakes that only show up during the first real storm. This guide explains how industrial flood seals work, which rubber compounds to choose, where to use them in warehouses, and how to deal with leaks and material failure so you go into the next rainy season with far more confidence.

Key Takeaways

Before we dive into the details, here is the big picture of how industrial flood seals support warehouse protection.

- Heavy-duty rubber door seals, water stoppers, and gate seals form the active edge of a barrier at doors, ramps, and gates. They close small gaps that rigid materials cannot, so floodwater cannot creep through weak points.

- Material choice directly affects performance and service life in the Philippines. EPDM resists sun, rain, and ozone, neoprene handles oil and fuel, while natural rubber offers high elasticity in protected zones. A poor material match shortens seal life and raises maintenance costs.

- Custom sealing profiles usually work better than generic strips when floors are uneven, spans are wide, or joints are complex. Shaping the seal to the exact gap and frame improves installation and long-term reliability, especially in older buildings and retrofits.

- Industrial flood seals perform best as part of a complete flood plan with barriers, drainage, and regular maintenance. When seals are inspected, cleaned, and replaced on schedule, they stay soft and responsive, which reduces the chance of failure during a strong storm.

Understanding Industrial Flood Seals For Warehouse Protection

When we talk about industrial flood seals, we mean the rubber components that sit between a flood barrier and the structure. They run along the bottom and sides of door frames, gates, and concrete joints, and they compress tightly when a barrier closes so water cannot pass through the contact surface.

There is a clear difference between static and dynamic sealing. Static seals sit on gaps that barely move, such as cast-in joints between concrete slabs. Dynamic seals work on parts that move every day, like swinging gates, sliding doors, and demountable panels. Flood seals in warehouses often have to cope with both, while still working as the building settles over time.

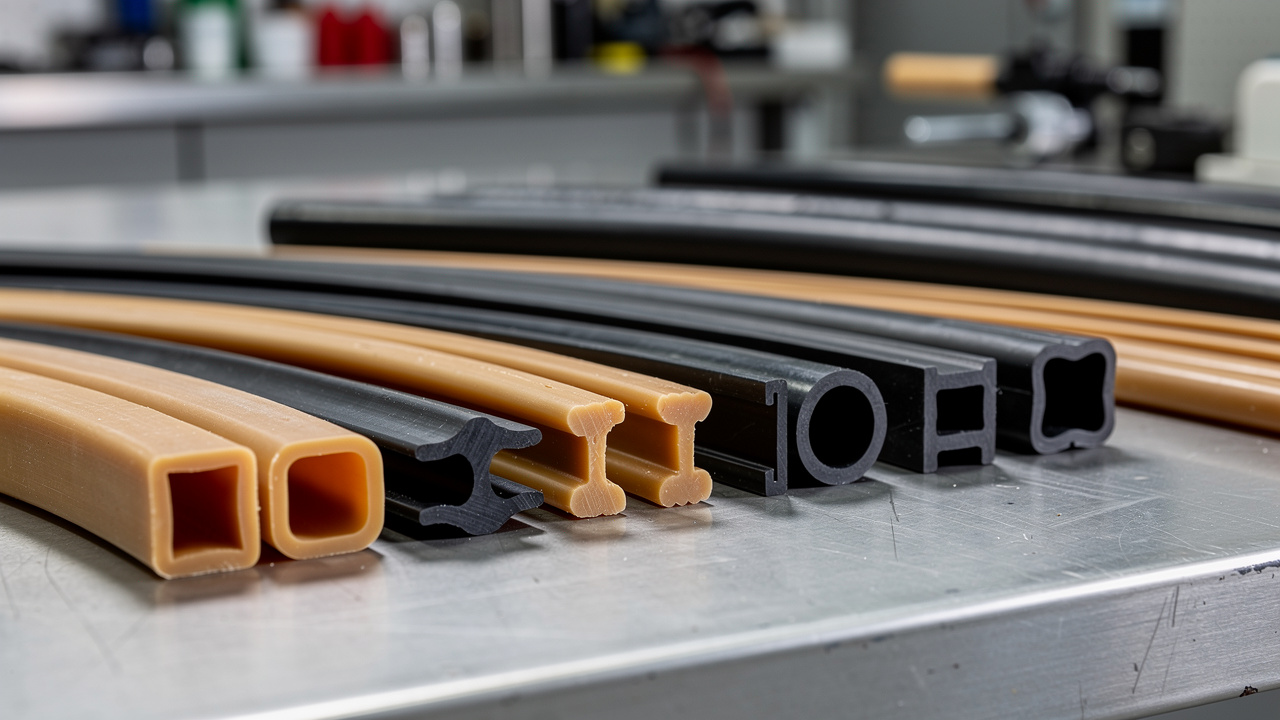

Rubber outperforms metal and many plastics in this role because it compresses, rebounds, and resists corrosion. Under hydrostatic pressure, water pushes against every millimeter of a barrier. A good rubber profile turns that pressure into a tighter seal by spreading contact across a wider area. At RK Rubber Enterprise Co., we group our products for these tasks into three main types: rubber door seals, rubber water stoppers, and rubber gate seals, which work together to keep warehouses dry.

Types Of Heavy-Duty Rubber Seals For Flood Barriers

For warehouse flood mitigation, we rely on several kinds of heavy-duty rubber seals matched to specific parts of the building. One profile may be ideal for a personnel door, while another suits a wide gate or buried joint. Pairing the right seal with the right barrier means the system performs under real flood conditions, not only on paper.

Rubber Door Seals

Rubber door seals protect the many smaller openings that often become early leakage paths. We design these as compression profiles along the door perimeter and threshold, so they press firmly when the door closes and create a continuous contact line on all sides.

Beyond blocking water under moderate to high levels, these seals also soften door impact and cut noise in busy warehouses. For the Philippine climate, we use compounds that resist sun, heat, and humidity so they do not crack or harden. Typical applications include personnel doors, dock access doors, and emergency exits, often combined with demountable panels that staff install when a flood warning is issued.

Rubber Water Stoppers

Rubber water stoppers protect hidden joints inside concrete and structural work. Buildings move a little over time because of settlement, temperature change, and even small earthquakes, and rigid fillers dislike that movement. Flexible water stoppers bridge these joints and keep a tight seal even when concrete on each side shifts.

For this role we often use EPDM or neoprene, which combine flexibility with strong resistance to chemicals and corrosion. Water stoppers can be embedded in fresh concrete during construction or installed as surface-mounted rubber strips during upgrades. They are especially important at expansion joints, cold joints between pours, and the base of ground-level barriers, where repeated movement can cause rigid materials to crack.

Rubber Gate Seals

Rubber gate seals handle wide openings where both water pressure and span are high: large driveways, perimeter flood gates, and tall demountable systems. These seals have extended contact surfaces that spread compression over a broad area, which helps them resist strong hydrostatic pressure without tearing or rolling out of place.

We manufacture gate seals in EPDM, natural rubber, or neoprene, based on expected water height and chemical exposure from trucks, fuel, or industrial liquids. In warehouses and plants, they are integrated with swing-gate barriers and demountable panels across loading yards. Because they can also contain liquids inside an area, they support both flood protection and chemical spill control.

“The seal profile is only a few centimeters wide, but it decides whether a barrier holds or leaks,” as one of our senior project engineers likes to remind clients.

Material Selection: Choosing The Right Rubber Compound

Choosing the right rubber compound is one of the most important steps when planning industrial flood seals for a warehouse. The wrong material may look fine at first but can harden, crack, or swell long before the barrier reaches its expected service life.

We commonly work with EPDM, natural rubber, SBR, and neoprene:

- EPDM suits outdoor door and gate seals because it resists strong sunlight, ozone, and rain.

- Natural rubber offers excellent elasticity and grip for sheltered areas with high mechanical wear.

- SBR works well where abrasion is high but exposure to oils is low.

- Neoprene is preferred near fuel, lubricants, or harsh cleaners because it resists many oils and chemicals better than EPDM.

Key properties we check include tensile strength, tear and abrasion resistance, compression set (how well the rubber springs back after long compression), and chemical resistance. Compatibility with concrete, steel, aluminum, coatings, and adhesives also matters, since a reaction with nearby materials can shorten seal life.

At RK Rubber Enterprise Co., we use high‑grade compounds and guide clients through these choices, balancing up-front cost with long service life and fewer replacements.

Strategic Applications And Customization For Warehouse Facilities

No two warehouses in the Philippines are exactly the same, so industrial flood seals must match real site conditions, not just drawings. We usually start with a site assessment, looking at floor levels, nearby waterways, past flood lines, and weak entry points. From there we define target water height, opening spans, and how daily operations move through each area.

Loading docks and cargo bays get special attention because they see the most traffic. A common setup is demountable barrier panels across the dock opening, with heavy-duty rubber door or gate seals along edges and floors. Seals must compress enough to stop water yet still allow quick installation and removal so trucks can keep moving outside flood alerts.

Basement entries and underground storage may use automatic flip-up barriers with molded seals that sit flush in the floor and frame, staying out of the way until water arrives. Low-lying or coastal sites also need perimeter protection at vehicle and pedestrian gates, where wide gate seals and water stoppers follow driveway slopes and tie into concrete walls.

Thanks to broad customization capacity at RK Rubber Enterprise Co., we can adjust profile dimensions, compounds, and mounting methods for both new projects and retrofits so flood protection supports, rather than disrupts, daily operations.

Addressing Common Challenges In Warehouse Flood Protection

After many projects, we keep seeing the same warehouse flood issues. Well-designed industrial flood seals can solve much of this, as long as they reflect real conditions on site.

One concern is leakage under high pressure. To keep this under control, we design seal profiles that build higher contact pressure as water pushes harder on the barrier. Careful control of material hardness and profile shape helps the seal compress enough without cutting or folding, so leakage stays low and predictable.

Another problem is material degradation from heat, sun, salt air, and chemicals. We counter this by using EPDM and neoprene compounds with strong weather and chemical resistance, rather than low‑grade materials that crack or swell after a few seasons.

Building movement is a third issue. Concrete slabs and steel frames shift with settlement and temperature, which can break rigid seals. Our rubber water stoppers and flexible profiles stretch and compress with that movement while still blocking water.

As one warehouse manager told us after a major storm, “The barrier looked solid, but the rubber made it work. Without the seals, the water would have walked straight in.”

Clear installation instructions and, when needed, custom profiles also help contractors fit seals correctly the first time, avoiding gaps and material clashes that shorten service life.

Conclusion

Floods in the Philippines do not wait for project schedules, but careful planning can keep a warehouse ready when water rises. Heavy-duty rubber seals at doors, gates, and joints turn rigid barriers into tight, reliable industrial flood seals that protect stock, machinery, and electrical rooms and help reduce downtime during strong weather.

Custom, high‑grade rubber sealing systems usually perform far better than generic strips or trial‑and‑error fixes. By matching compounds, rubber profiles, and mounting details to each opening, you can cut leakage, extend service life, and lower the real cost per year of protection.

At RK Rubber Enterprise Co., we combine ISO 9001‑based quality control with local knowledge of Philippine sites and weather. If you manage a warehouse, plant, or commercial facility, our team is ready to review your site and recommend practical industrial flood seals so you can face the next rainy season with confidence.

FAQs

Before closing, we want to answer some of the questions we hear most often about industrial flood seals for warehouses and similar facilities.

Question 1: What Is The Difference Between EPDM And Neoprene Rubber Seals For Flood Barriers?

EPDM rubber offers excellent resistance to sunlight, ozone, and rain, so it is usually the first choice for outdoor door and gate seals. Neoprene handles contact with oils, fuel, and many chemicals better, while still giving reasonable weather resistance. For most external industrial flood seals we suggest EPDM; near fuels, oils, or chemical handling we often move to neoprene.

Question 2: How Long Do Heavy-Duty Rubber Flood Seals Typically Last?

Service life depends on material quality, exposure, and maintenance, but well-specified industrial flood seals can last many years. Strong sunlight, frequent chemical contact, and heavy mechanical wear shorten that life, while protection from these factors extends it. We always recommend regular inspection so seals can be replaced before their performance drops during a flood event.

Question 3: Can Rubber Seals Be Customized For Existing Warehouse Flood Barrier Systems?

Yes. We regularly design custom rubber profiles to fit existing gates and barrier frames. We begin with measurements, drawings, or site photos to study current gaps and fixing methods, then adjust profile shape and compound so the new industrial flood seals fit the old hardware while giving better sealing performance.

Question 4: How Do Rubber Seals Accommodate Building Movement Without Losing Effectiveness?

Rubber has natural elasticity, so it stretches and compresses with small shifts in the structure and then returns to its original shape. Our water stoppers and flexible profiles are shaped to allow controlled compression and expansion across joints and interfaces. Rigid materials tend to crack or pull away when a slab moves; a well‑designed rubber seal continues to block water and greatly reduces the chance of joint failure during a flood.

Leave a Reply

Want to join the discussion?Feel free to contribute!