Trusted Rubber Manufacturer in the Philippines

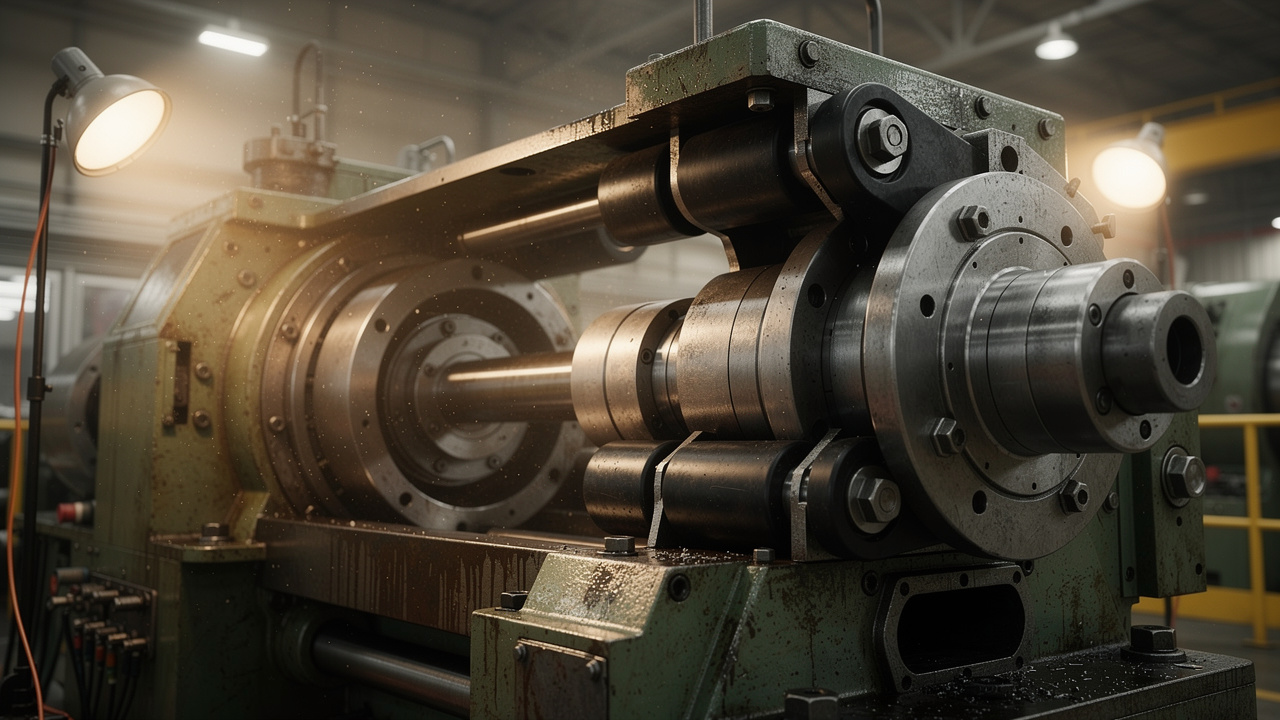

One weak rubber gasket can stop an entire production line. One worn-out rubber bushing can shut down a conveyor, delay deliveries, and push costs higher. That is why choosing a trusted rubber manufacturer is not just a purchase decision; it is a risk management decision that affects safety, uptime, and profit.

We built RK Rubber Enterprise Co. around this reality. As one of the most trusted rubber manufacturing partners in the Philippines, we focus on engineered rubber parts that keep plants, vehicles, and structures running safely and reliably. Our vision is to act as a real catalyst for Philippine industry and help our country stand as a major exporter of quality rubber products, not just a buyer.

“Quality is not an act, it is a habit.” – Aristotle

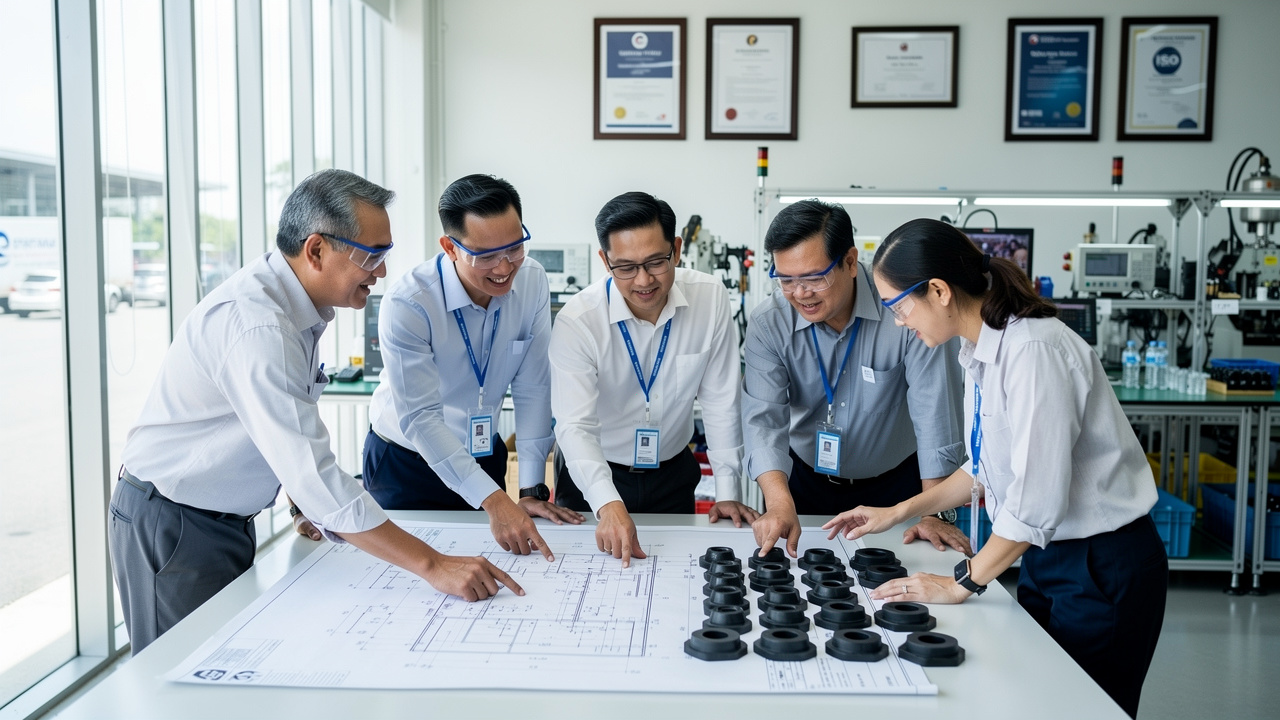

Our team designs and produces sealing parts, shock and vibration control items, and specialized components for industrial, automotive, construction, marine, and many other applications. We support these with strict quality control based on global standards such as ISO 9001, ASTM, DIN, FDA, and RoHS, so clients can verify how we work, not just rely on promises. As a trusted rubber supplier, we also share technical know-how to help prevent design and installation errors.

In this article, we walk through what really defines a trusted rubber manufacturer in the Philippines and how we stand out. We explain our product range, how we address common industrial problems, and why many leaders treat us as a long-term partner instead of a simple vendor. By the end, you will see how working with the right trusted rubber manufacturer can protect your operations and lower your total cost over time.

Key Takeaways

- A trusted rubber manufacturer proves its value through consistent quality, reliable lead times, open communication, and clear compliance with standards such as ISO 9001, ASTM, DIN, FDA, and RoHS that industrial buyers can check and audit. This kind of partner keeps equipment safe and downtime under control. This is exactly how we position RK Rubber Enterprise Co.

- Our company stands out through our focus on quality, deep customization across almost every product, and a partnership mindset that treats client projects as our own. We serve automotive, construction, marine, power generation, water management, commercial facilities, and more sectors across the Philippines.

- We combine strict quality control with flexible design and production, plus eco-friendly practices in our plant. That means we act as a trusted rubber supplier that can adapt to urgent changes while still following ISO 9001, ASTM, DIN, FDA, and RoHS guidelines and supporting more sustainable manufacturing.

What Defines A Trusted Rubber Manufacturer In The Philippines?

When plant managers and engineers talk about a trusted rubber manufacturer, they are talking about more than just a company that ships parts on time. Trust in manufacturing means:

- Steady quality from batch to batch

- Honest and realistic lead times

- Clear documentation and traceability

- Technical support when issues appear

- Long-term capacity to support repeat and expansion orders

For us, this starts with quality and reliability. We choose high-grade compounds such as EPDM, Silicone, Viton, and Nitrile, and we match them carefully to each application. Every stage of production goes through dimensional checks, hardness tests, and visual inspections under a zero-defect mindset. As a trusted rubber manufacturer in the Philippines, we follow international standards like ISO 9001, ASTM, DIN, FDA, and RoHS so clients can trace how every product was made and confirm that specifications were followed.

“You can’t inspect quality into a product; it is already there.” – W. Edwards Deming

Safety and environmental care are also core pillars. Our rubber bumpers, pads, seals, and bushings are designed to protect both people and equipment under heat, chemicals, movement, and heavy load. At the same time, we follow Philippine regulations and apply cleaner practices in our plant, with waste reduction and responsible material handling. This helps us act as a trusted manufacturer for companies that care about both worker safety and environmental impact.

Real trust grows over time. A trusted rubber manufacturer shows a record of serving many kinds of industries, from automotive OEMs to construction and marine projects across NCR, Visayas, and Mindanao. When rubber products last longer, machines fail less, and sites stay safe, clients see lower downtime, lower total cost of ownership, and better project results. That is the standard we work toward in every order.

Our Comprehensive Range Of Industrial Rubber Products

As a trusted rubber manufacturer, we do not think of our products as simple parts on a list. We design them as working answers to sealing, safety, and performance issues that plant managers and engineers face every day. Across all categories, we provide customization so each part fits the job, not the other way around. This is what helps us act as a true trusted rubber supplier instead of a generic source.

We provide sealing parts that protect against leaks, contamination, and pressure loss. Key products include:

- Silicone rubber gaskets that handle temperatures up to 250°C while resisting fluids, ozone, oil, and fire, making them a strong choice for power plants, food processing, and chemical facilities

- Rubber profiles in sponge, solid, hybrid, and co-extruded designs for windows, doors, and openings in buildings, vehicles, and machines

- Rubber strips made from natural, synthetic, and neoprene compounds for simple yet effective sealing in panels, covers, and enclosures

Our door and gate seals use EPDM, Natural Rubber, SBR, and other blends to keep water, dust, and noise under control across industrial plants, commercial buildings, and residential projects. We also design rubber piston rings that limit gas leakage and wear inside engines and cylinders, which helps extend equipment life and maintain performance over longer operating hours. As a trusted rubber manufacturer in the Philippines, we build each of these sealing parts with long-term performance in mind, not just first-day fit.

Shock and vibration control is another key part of our work. We produce rubber bushings for automotive suspension, construction machines, industrial equipment, and marine hardware to stabilize movement and absorb impact. Our shock absorbers, rubber cushion, rectangular bumpers, rubber pads, and rubber footings help protect floors, frames, and people from repeated shocks and loud vibration. These products support safer workplaces, higher worker comfort, and longer life for motors, bearings, and structures.

We also cover specialized rubber components needed in more focused applications, such as:

- Rubber tubing using EPDM, Neoprene, Silicone, Viton, Nitrile, and blended compounds for medical, food, and industrial lines where flexibility and chemical resistance are vital

- Custom rubber balls, linings, and shaped parts for equipment makers that require specific sizes and performance properties

- Rubber water stoppers for dams, tunnels, and buildings that bend with structural movement and resist corrosion, giving better long-term performance than metal stoppers

Across all these groups, we keep customization open so every client can get parts that match their exact drawings and requirements.

How We Address Critical Industrial Challenges

Every plant, project site, or assembly line has its own pain points, and a trusted rubber manufacturer must help remove them, not add new ones. When we talk with plant managers, project engineers, and buyers, we focus first on what keeps them up at night. Only then do we decide which rubber parts, compounds, or designs will give the best answer.

The most common challenges we see include:

- High temperatures and harsh chemicals

- Persistent leaks and contamination

- Excessive vibration, movement, and noise

- Parts that fail early because materials are mismatched to the application

Many facilities work with extreme temperatures and aggressive chemicals. For these cases, our silicone rubber gaskets handle heat up to 250°C and resist oils, steam, and strong cleaning agents, which suits power generation, petrochemical, and food-grade systems. We also help prevent sealing failures by using well-designed rubber profiles, strips, and piston rings that keep leakage low, reduce unplanned shutdowns, and cut the need for constant maintenance work. This is where a trusted rubber manufacturer can save far more money than the basic cost of the part.

Movement and safety bring another set of challenges. In construction and water infrastructure, our rubber water stoppers provide the flexibility that metal stoppers cannot match, so joints can move without cracking. To reduce workplace hazards, our cushions and pads cut vibration and noise around heavy equipment, which supports worker safety and comfort. When clients bring in highly specific needs, we adjust sizes, shapes, colors, hardness levels, and material mixes to match those demands. We do this through close discussion, drawings, and testing, which turns us into a trusted rubber supplier and problem-solving partner, not just a catalog.

“The bitterness of poor quality remains long after the sweetness of low price is forgotten.” – Most often attributed to Benjamin Franklin

Why Industrial Leaders Choose RK Rubber Enterprise Co.

When we speak with industrial leaders, many say they do not want just any rubber vendor. They want a trusted rubber manufacturer that stands with them from design to installation and beyond. We built RK Rubber Enterprise Co. around that kind of relationship, so our role is closer to a technical partner than a simple vendor.

Our quality assurance is something clients can verify, not just hear in a sales pitch. We use dimensional checks, hardness tests, and visual inspections from raw material up to final packing. Our work follows ISO 9001 and aligns with international guidelines like ASTM, DIN, FDA, and RoHS, and we draw from practices used in ISO 14001 and IATF 16949 environments. This focus on system-based quality is a main reason many firms call us their most trusted rubber manufacturer and trusted supplier.

Customization is also a core strength. We adjust sizes, shapes, colors, hardness levels, and rubber compounds so that each part fits exactly what the machine or structure needs. Our team works with EPDM, Neoprene, Silicone, Viton, Nitrile, natural rubber, and blended materials, and we support both simple parts and very detailed custom pieces. By sharing our experience early in the design stage, we help clients avoid errors that can appear later during installation or operation.

At the same time, we know cost and timing matter as much as quality. Our manufacturing facility can handle large runs while still giving careful attention to custom jobs, which keeps lead times realistic and deliveries on schedule. We focus on cost-efficient quality rubber products, so clients do not have to choose between price and performance. We also follow eco-friendly and more sustainable practices in our production, and our mission is clear: satisfy and go beyond expectations through responsive support, clear communication, and lasting partnerships across the Philippines.

Conclusion

Choosing a truly trusted rubber manufacturer is one of the most important decisions an industrial buyer can make. The right partner protects uptime, keeps people safe, and guards every project budget from hidden costs that come from poor quality parts.

At RK Rubber Enterprise Co., we combine strict quality control, wide customization, and a strong customer-focused approach to act as a trusted rubber manufacturer and trusted rubber supplier for many Philippine companies. We already support automotive, construction, marine, power, water, residential, and commercial projects across NCR, Visayas, and Mindanao, and we keep pushing Philippine rubber manufacturing toward global standards.

If you want a partner that will listen, share expertise, and respond fast when requirements change, we are ready to help. Reach out to us for a technical consultation, a custom quote, or to discuss any rubber requirement for your plant or project. Let us show you how the RK Rubber difference can support your success for the long run.

FAQs

What Industries Does RK Rubber Enterprise Co. Serve In The Philippines?

We serve a wide range of industrial rubber products across the country. Our clients include mechanical engineering firms, automotive manufacturers and OEM suppliers, marine and shipbuilding companies, and operators of industrial machinery. We also support construction, power generation, and water management projects, along with aerospace, agriculture, residential, and commercial developments. From NCR to Visayas and Mindanao, we work with both large industrial plants and highly specialized applications.

How Does RK Rubber Ensure Product Quality And Consistency?

We apply strict quality control at every stage of production. Our team performs dimensional checks, hardness tests, and visual inspections from incoming raw materials to finished products. We follow international standards such as ISO 9001 along with ASTM, DIN, FDA, and RoHS guidelines. We apply a zero-defect mindset and always look for ways to improve our processes. Our manufacturing facility supports this approach and helps us deliver reliable, long-lasting parts.

Can RK Rubber Create Custom Rubber Products To My Exact Specifications?

Yes, customization is one of our strongest points as a trusted rubber manufacturer. We can adjust sizes, shapes, colors, hardness levels, and material mixes across almost all product types. Our team works closely with you to understand the application, refine the drawings, and choose the right rubber compounds such as EPDM, Neoprene, Silicone, Viton, Nitrile, natural, synthetic, or blended options. We handle both simple shapes and very complex designs. You can contact us anytime to discuss your specific requirements.

What Makes RK Rubber Different From Other Rubber Suppliers In The Philippines?

Three things stand out for our clients:

- A strong quality commitment with strict controls and alignment with ISO 9001, ASTM, DIN, FDA, and RoHS standards

- True customization, acting as a trusted rubber supplier that designs parts around real-world needs rather than forcing standard items into critical applications

- Products that offer strong performance, from temperature resistance up to 250°C to durability and chemical resistance, all at competitive prices

We also follow eco-friendly production practices and work toward our vision of helping the Philippines grow as a major global exporter of rubber products. Our goal is to exceed expectations and build long-term, trust-based partnerships with every client we serve.

Leave a Reply

Want to join the discussion?Feel free to contribute!