UV Resistant Rubber for Philippine Outdoor Use

Introduction

A cracked rooftop chiller seal or brittle pump gasket might look harmless at first. A few months later, that same defect can turn into a leak, a shutdown, or even a safety issue. Very often, the real cause is ozone cracking and a poor choice of UV resistant rubber for Philippine conditions.

Ozone in the air attacks certain rubber types, starting as fine surface lines and growing into deep, straight fissures along stretched areas. At the same time, strong sunlight triggers UV damage that hardens, chalks, and embrittles rubber that once was flexible and safe.

The Philippine climate speeds this up: intense sun, high UV index, hot surfaces, humidity, and ozone from traffic and industry all act together. For plant managers, contractors, and facility teams, that means more downtime and faster replacement if the wrong material is used.

This guide explains how ozone and UV damage rubber, which materials stand up best in the Philippines, how to choose the right UV resistant rubber, and how RK Rubber Enterprise Co. supports projects with Philippine-optimized compounds and technical guidance.

Key Takeaways

- EPDM and Silicone are the most reliable choices for UV resistant rubber in outdoor Philippine applications. EPDM covers most general needs; Silicone is better for very high temperatures or critical sealing.

- Material choice must balance UV and ozone resistance with temperature limits, chemical exposure, mechanical stress, and budget. A rubber that survives sun but fails in contact with oil or chemicals still causes downtime.

- Philippine weather accelerates aging through strong UV, hot surfaces, humidity, and ozone. Correct UV resistant rubber can extend replacement intervals three to five times compared with unsuitable compounds.

- Nitrile and Natural Rubber perform well for oil resistance and abrasion under cover, but they crack quickly under sun and ozone. For outdoor use, EPDM, Silicone, Neoprene, Butyl, Viton, PVC, or TPE are usually better fits.

- Working with an experienced local manufacturer such as RK Rubber Enterprise Co. helps cut risk. Local compounding, practical material selection, and sound storage, installation, and inspection practices all extend service life.

Understanding Ozone Cracking And UV Degradation In Rubber

To choose the right UV resistant rubber, it helps to know what actually attacks elastomers outdoors. Two main factors work together: ozone and ultraviolet (UV) light.

Many common rubbers (especially Natural Rubber and Nitrile) have double bonds in their polymer backbone. Ozone targets these bonds, starting microcracks on stressed surfaces. These lines grow deeper and longer until full splits appear — this is ozone cracking.

UV damage follows a different path but has a similar effect. UV light breaks chemical bonds inside the rubber. Stabilizers slow this down, but once enough bonds break, the material loses elasticity, hardens, turns chalky, and begins to crack. Research on the impact of UV rays on high-performance rubber components confirms how prolonged exposure accelerates these degradation processes. Heat and daily expansion–contraction cycles push this damage even faster.

The Philippine Climate Factor A Perfect Storm For Rubber Degradation

What might take years in mild climates can happen in a fraction of the time in the Philippines, as a study on performance and aging under prolonged UV exposure demonstrates:

- Very high UV index for much of the year, especially on roofs, vehicles, ports, and open plants.

- Hot surfaces, with dark rubber easily exceeding 60 °C in direct sun, and even higher near metal roofs or hot equipment.

- Humidity and pollutants, which speed chemical reactions and carry ozone and reactive gases from traffic, generators, and high-voltage gear.

- Monsoon cycles, with repeated wet/dry and swell/shrink movements that help cracks open wider.

When we specify UV resistant rubber for Philippine projects, we always consider this full package of stresses, not just a single UV test result.

Top UV-Resistant Rubber Materials For Philippine Applications

Not all elastomers behave the same under sun and ozone. Some have saturated backbones or special chemical groups that resist attack. For Philippine outdoor use, four stand out again and again:

- EPDM (Ethylene Propylene Diene Monomer)

- Silicone Rubber

- Viton (FKM)

- Butyl Rubber (IIR)

Each offers a different blend of temperature range, chemical resistance, mechanical properties, and cost. Often, the best design uses more than one of these in different parts of the same system.

“Environment beats material every time if you pick the wrong compound.”

— common saying among rubber technologists

EPDM Ethylene Propylene Diene Monomer The Versatile Workhorse

EPDM is our go-to recommendation for general-purpose UV resistant rubber outdoors in the Philippines.

- Strengths: Outstanding resistance to ozone, UV, rain, and aging thanks to its saturated backbone; good flexibility down to around −40 °C and up to about 120 °C (higher for some grades); very good resistance to water, steam, diluted acids and alkalis, alcohols, and many polar fluids.

- Limits: Poor resistance to petroleum oils, fuels, and many non-polar solvents.

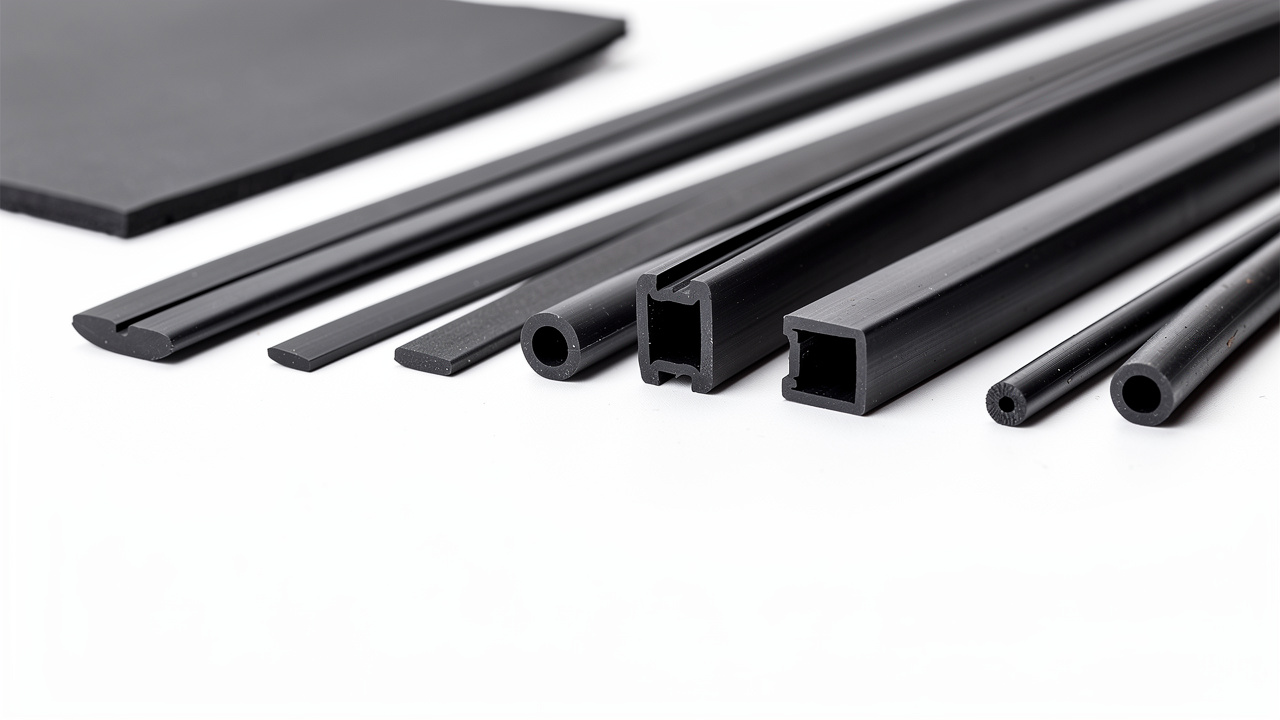

In practice, EPDM stays springy for years, keeping sealing pressure on windows, doors, roofs, and outdoor machinery. At RK Rubber Enterprise Co., we supply EPDM sheets, extruded profiles, and custom parts formulated specifically for Philippine weather so clients get long outdoor life without Silicone-level pricing.

Silicone Rubber Extreme Temperature Champion

When temperature and weather exposure are both demanding, Silicone is hard to beat.

- Strengths: Very wide temperature range (roughly −60 °C to about 260 °C, depending on grade), excellent UV and ozone resistance, and good stability under rapid temperature swings.

- Typical uses: High-temperature gaskets, oven doors, LED fixtures, architectural glazing, equipment near burners or heaters that also face sun and rain.

Silicone does not bond easily with common adhesives, so surface preparation and the right Silicone-based adhesive or primer are important. RK Rubber Enterprise Co. manufactures Silicone gaskets and sheets for high-temperature and outdoor exposure in food processing, industrial ovens, and architectural projects.

Viton FKM The Ultimate Performance Answer

Viton (FKM) is a fluoroelastomer developed for very harsh environments.

- Strengths: Outstanding resistance to oils, fuels, many solvents, aggressive chemicals, and high temperatures (often up to around 200 °C in continuous service); very good UV and ozone resistance.

- Typical uses: Chemical plant valves, refinery equipment, fuel system parts, and other high-value assets where both chemicals and strong sunlight are present.

The trade-off is cost: Viton parts are several times more expensive than EPDM. For many outdoor applications, EPDM or Silicone already provide enough performance. We reserve Viton for outdoor areas with both high chemical load and strong sun, where lower-grade rubbers would fail quickly.

Butyl Rubber IIR The Impermeable Barrier

Butyl Rubber (IIR) is special because of its extremely low gas and moisture permeability.

- Strengths: Excellent resistance to ozone, UV, heat, and aging, plus very low gas permeability. Good resistance to many acids and alkalis.

- Typical uses: Tank and pond liners, gas covers, stoppers, and seals where gas leakage must remain very low, such as wastewater tank covers exposed to sun and rain.

When gas tightness and vapor control rank higher than everything else, Butyl is often the best choice. When general outdoor weathering and flexibility are the main needs, EPDM usually comes first.

Quick Comparison Of Key Materials

| Material | UV / Ozone Resistance | Typical Temperature Range (°C) | Oil / Fuel Resistance | Typical Outdoor Uses |

|---|---|---|---|---|

| EPDM | Excellent | −40 to 120 (higher for some grades) | Poor | Roofs, door/window seals, outdoor gaskets, cable covers |

| Silicone | Excellent | −60 to 260 (grade-dependent) | Moderate | High-temp gaskets, ovens, lighting, glazing |

| Viton (FKM) | Very good | −20 to 200 (grade-dependent) | Excellent | Chemical and fuel systems, harsh industrial sites |

| Butyl (IIR) | Excellent | −40 to 110 (approx.) | Moderate | Gas barriers, tank liners, covers |

Good Alternative Materials Balancing Multiple Requirements

Real projects often need more than UV and ozone resistance. Oil splash, fuels, processing methods, or visual requirements can shift the choice toward other materials.

Neoprene offers a middle ground between weathering resistance and oil resistance. PVC and TPE give good outdoor life for many light industrial and consumer products at attractive costs, often with wide color choices.

Neoprene CR The Balanced Performer

Neoprene (CR) is a synthetic rubber that balances moderate UV resistance with moderate oil resistance.

- Works from roughly −40 °C to about 100 °C.

- Handles outdoor sun for several years, though not as long as EPDM in pure weather exposure.

- Offers better resistance to oils and greases than EPDM, at a similar price range.

Common uses include gaskets and hoses that see both sunlight and occasional oil contact, such as engine compartment seals, outdoor hoses with oil mist, or protective boots on exposed joints. RK Rubber Enterprise Co. produces Neoprene strips, sheets, and profiles for these mixed exposure cases.

Thermoplastic Alternatives PVC And TPE

Thermoplastics like PVC and TPE process like plastics but behave like softer rubbers.

- PVC: Can be made from rigid to flexible; with the right stabilizers it offers good weathering resistance and many color options. Used in window frames, siding, cable covers, light-duty tubing, and decorative trim.

- TPE: Feels more like soft rubber, with many grades showing good ozone and UV resistance. Common in grips, seals, and flexible tubing on outdoor tools and consumer products.

We suggest PVC or TPE when low weight, complex shapes, or bright colors matter, and when temperatures and chemicals stay within moderate ranges.

Materials To Avoid For Outdoor Philippine Applications

Some of the most common rubbers in industry age very quickly outdoors in the Philippines. Nitrile (NBR), Natural Rubber, and SBR have unsaturated backbones that ozone attacks easily, as aging studies of polymer blends have documented. They may work very well indoors or under cover, yet fail fast in open sun.

Knowing where these rubbers belong — and where they do not — is an important part of any UV resistant rubber plan.

Nitrile NBR Oil-Resistant But UV-Vulnerable

Nitrile (NBR) is excellent against oils, fuels, and greases, which is why it is common in engines, hydraulics, and fuel systems.

Outdoors in the Philippines, however, NBR hardens and cracks quickly under sun and ozone, often within months. It remains a strong choice indoors or in shaded housings, but for exposed equipment that also sees oil, we usually move to Neoprene, Viton, or a design that keeps NBR inside a protected housing while EPDM or Silicone handle the outer weather seal.

Natural Rubber And SBR Indoor Performers Only

Natural Rubber and SBR (Styrene Butadiene Rubber) offer high tensile strength and very good abrasion resistance, which is why they are common in tires, conveyor belts, and impact pads.

Under Philippine sun, both lose flexibility, become sticky, then hard and brittle. Cracks deepen and pieces can flake off. They perform well for indoor impact pads, vibration mounts, and conveyor systems, but they are poor choices for exposed roof seals, outdoor joints, or long-term sun exposure unless heavily shielded and expected life is short.

Critical Selection Criteria Beyond UV Resistance

UV and ozone resistance matter, but they are only part of the selection picture. A gasket that handles sunlight but fails from heat, chemicals, or repeated movement still causes trouble.

When we specify UV resistant rubber for Philippine sites, we review temperature range, chemical exposure, mechanical demands, installation method, and expected service life.

Temperature Requirements And Thermal Cycling

Dark rubber in direct sun can be much hotter than the surrounding air, especially near metal roofs, boilers, ovens, or engines. Daily swings between cool nights and hot days cause expansion and contraction, adding fatigue.

- EPDM covers most outdoor needs up to about 120 °C.

- Silicone or Viton are safer when continuous temperatures are higher or when rapid temperature swings are common.

Cold performance matters less locally, but it is important for exported equipment or parts stored in chilled warehouses.

Chemical And Fluid Exposure Assessment

Chemicals and fluids can destroy rubber faster than UV. We always ask:

- Which acids, bases, solvents, oils, fuels, cleaners, or process chemicals are present?

- Are exposures constant, occasional, or only during cleaning?

Common patterns:

- UV + oils/fuels: Neoprene or Viton, or shielded Nitrile.

- UV + water/steam/diluted chemicals: EPDM or Butyl.

- UV + high temperature + aggressive chemicals: Viton or Silicone.

At RK Rubber Enterprise Co., we map real chemical exposure against material compatibility before any order is finalized.

Mechanical Properties And Physical Demands

Mechanical demands can be as important as weathering:

- Compression set: Affects long-term sealing force in gaskets. EPDM and Silicone often perform better than cheaper rubbers.

- Tensile strength and elongation: Matter in expansion joints or flexible couplings.

- Abrasion and tear resistance: Key in conveyor systems, impact pads, and linings.

We match hardness, thickness, and mechanical properties with environmental resistance so the part survives both physical loads and weather.

RK Rubber Enterprise Co. UV-Resistant Offerings For Philippine Weather

As a Philippine manufacturer, RK Rubber Enterprise Co. sees firsthand how quickly the wrong rubber fails outdoors. Our product lines focus on compounds that stand up to local UV, ozone, heat, and humidity, backed by field feedback and quality control.

We provide EPDM sheets and profiles, Silicone gaskets and sheets, rubber linings, door seals, and custom items for many industries, along with technical support on design and maintenance.

Our EPDM Product Range Engineered For Philippine Outdoor Applications

Our EPDM products include:

- Sheets from about 1 mm to around 40 mm thickness for roofing membranes, pads, and cut gaskets.

- Solid and sponge profiles for doors, windows, panels, and equipment enclosures.

These EPDM compounds are formulated with stabilizers suitable for Philippine UV and humidity. They perform well on commercial roofs, vehicle weather stripping, cable covers, and other outdoor seals in contact with water, steam, and many diluted chemicals.

Silicone Rubber Gaskets And Sheets Premium Performance For Extreme Conditions

For high temperature and demanding sealing, we supply Silicone gaskets and sheets that:

- Handle heat up to around 250 °C (grade-dependent).

- Resist UV, ozone, and many cleaning cycles.

- Retain flexibility across a wide temperature range.

Typical applications include baking ovens, dryers, sterilizers, food processing lines, architectural glazing, and lighting fixtures that face both heat and strong sun. We also advise clients on adhesives, primers, and installation practices for Silicone.

Custom Rubber Products And Expert Support

Many Philippine projects need custom profiles, shapes, or linings. RK Rubber Enterprise Co. designs:

- Rubber linings for tanks, chutes, and pipes that face wear, corrosion, and sometimes sun at exposed edges.

- Door seals and specialized profiles that keep water, dust, and noise out of buildings and equipment.

We support clients with material selection, seal geometry, bonding methods, and inspection plans. Because production is local, we can respond quickly to design changes and urgent site needs.

Best Practices For Maximizing Service Life

Even the best UV resistant rubber lasts longer when stored, installed, and maintained correctly. Poor handling can cut service life in half, no matter how good the compound is.

“Paying a little more attention up front is cheaper than paying for the same repair again and again.”

— common view among maintenance managers

Proper Storage And Handling Before Installation

Good storage slows natural aging:

- Keep rubber in a cool, dry, dark area (roughly 10–25 °C).

- Avoid direct sunlight, weather, and strong ozone sources (motors, welders, UV lamps).

- Store away from open containers of solvents, fuels, or aggressive cleaners.

- Use first-in, first-out stock rotation, and keep items in original wrapping until use.

During handling, avoid dragging over sharp edges, over-stretching, or contaminating with oils that are not part of the intended service.

Installation Techniques For Optimal Performance

Correct installation prevents early failure:

- Clean and dry all contact surfaces; remove dust, rust, old adhesive, and oils.

- Use primers and adhesives compatible with the specific rubber and substrate, especially for EPDM and Silicone.

- Avoid excessive stretching or compression; both raise stress and encourage cracking or permanent flattening.

- Round sharp metal edges that touch rubber.

RK Rubber Enterprise Co. often helps clients prepare simple installation guides so crews follow consistent, sound practices.

Inspection And Maintenance Protocols

Regular inspection catches problems early:

- For critical outdoor seals and linings, inspect visually at least quarterly; less critical parts can be checked annually.

- Look for chalking, discoloration, surface cracks, hardening, or loss of shape.

- Press a thumb into the rubber to feel for stiffness or slow rebound.

- Clean with mild soap and water; avoid petroleum-based cleaners on EPDM.

When repeated inspections show growing cracks or hardening, plan replacement during scheduled shutdowns rather than waiting for a leak or break.

Industry-Specific Applications In The Philippines

Each sector faces its own combination of sun, heat, chemicals, and mechanical stress. The right UV resistant rubber for a vehicle is not always the same as for a roof or a chemical plant.

Automotive Manufacturing And Transportation

In automotive work:

- EPDM is standard for window, door, trunk, and sunroof seals that must block rain and dust while facing strong sun.

- Under the hood, Neoprene and other special rubbers handle both heat and contact with oils and fuels.

- Interior parts also see UV through glass; materials must resist fading and cracking.

RK Rubber Enterprise Co. supplies custom profiles and parts for OEM and aftermarket clients who must meet performance standards under Philippine driving and parking conditions.

Construction And Infrastructure Projects

In buildings and infrastructure:

- EPDM membranes are widely used for flat roofs and terraces, offering long-term waterproofing and UV resistance.

- EPDM expansion joint profiles allow movement in buildings and bridges without cracking.

- Silicone sealants and gaskets are common in glazing and curtain walls, bonding glass to frames and withstanding sun and temperature swings.

We support contractors and designers with EPDM sheets, profiles, and guidance on where EPDM, Silicone, or other elastomers best fit the building envelope.

Industrial And Manufacturing Facilities

Industrial plants often combine chemicals, heat, vibration, and weather:

- EPDM gaskets and covers protect outdoor housings, pump bases, and control cabinets.

- Viton or special EPDM grades may be needed where aggressive chemicals are present.

- Silicone gaskets serve in high-temperature dryers, ovens, or food processing lines with frequent hot cleaning.

- Rubber linings and vibration mounts must handle wear and weather at the same time.

We work with plant teams to specify linings, high-temperature gaskets, profiles, and covers that cut leaks, protect workers, and reduce unplanned maintenance.

Cost-Benefit Analysis Investing In Quality UV-Resistant Rubber

Focusing only on price per meter or per gasket often hides larger costs that appear later. For outdoor Philippine use, the wrong rubber can trigger repeated replacements, emergency work, and damage to nearby equipment.

A better approach is to look at total cost of ownership: material, labor, downtime, and follow-up repairs.

True Cost Of Material Failure

When an outdoor rubber part fails:

- You pay for replacement parts, adhesives, and hardware.

- Labor to remove, clean, and reinstall often costs more than the part itself.

- Unplanned downtime can disrupt production, delay projects, and require overtime.

- Secondary damage (water ingress, corrosion, misalignment, safety incidents) can multiply the total cost.

A Nitrile seal that fails every year may look cheap at first, but over five years, repeated material, labor, and downtime often cost far more than a higher-grade EPDM part that lasts the full period.

ROI Of Premium Materials And Expert Partnerships

A simple life-cycle view helps:

Total cost = Initial material + (Replacement cost × Number of replacements) + Downtime + Extra maintenance

When you compare options this way:

- A more expensive EPDM or Silicone part that lasts five to ten years often costs less over time than a cheaper Natural Rubber or Nitrile part replaced every year.

- Fewer unexpected failures reduce emergency callouts, overtime, and rushed purchases.

- Using a technical partner like RK Rubber Enterprise Co. lowers the risk of wrong material choices and early failures.

Clients who shift to higher-grade UV resistant rubber and sound design support often see strong returns through longer service life and fewer shutdowns.

Conclusion

Rubber selection for outdoor Philippine use is a strategic choice that affects safety, uptime, and long-term cost. Strong UV, high temperatures, humidity, and ozone push many standard rubbers beyond their limits.

EPDM and Silicone stand out as the most reliable UV resistant rubber options outdoors, while Viton, Butyl, Neoprene, PVC, and TPE cover specific needs such as harsh chemicals, gas barriers, moderate oil contact, or appearance.

Good design looks at more than UV ratings. It considers temperature, chemicals, mechanical loads, installation, and realistic service life — and it weighs total cost across years, not just purchase price.

RK Rubber Enterprise Co. aims to be a technical partner as well as a supplier, offering EPDM sheets and profiles, Silicone gaskets and sheets, linings, door seals, and custom products tailored to Philippine conditions, along with guidance on installation and maintenance.

If your current seals, gaskets, or linings are cracking, chalking, or needing frequent replacement, it may be time to review your material choices and consider better UV resistant rubber options.

FAQs

Outdoor rubber performance in the Philippines raises many practical questions. Below are some of the ones we hear most often at RK Rubber Enterprise Co.

Question 1 What Is The Most Cost-Effective UV-Resistant Rubber For General Outdoor Use In The Philippines

For most general outdoor applications, EPDM is the best value UV resistant rubber:

- It handles strong sunlight, ozone, rain, and temperature swings much better than many common elastomers.

- Its cost is moderate, well below Silicone or Viton.

Neoprene only becomes more attractive when moderate oil resistance is also required. If operating temperatures stay below about 120 °C and there is no direct contact with petroleum oils, EPDM usually gives the best balance of service life and spending. RK Rubber Enterprise Co. keeps a wide EPDM range in stock specifically for Philippine weather.

Question 2 How Long Should UV-Resistant Rubber Last In Philippine Weather Conditions

Actual service life depends on material, design, and exposure, but typical ranges are:

- EPDM: About 10–20 years on roofs, door seals, and outdoor gaskets when well designed and maintained.

- Silicone: Often 15–25 years or more under strong sun and high temperature when chemicals are compatible.

- Neoprene: Around 5–10 years outdoors, depending on sun exposure and oil contact.

- Nitrile / Natural Rubber outdoors: Often show serious cracking and hardening within 6–18 months, which is why we avoid them for exposed service.

Sun hours, ozone levels, operating temperature, mechanical movement, and storage/installation practices all influence these numbers. We provide realistic life estimates and inspection advice based on specific products and applications.

Question 3 Can I Use Nitrile Rubber Outdoors If I Protect It With A Cover Or Coating

Covers, paints, and coatings can slow UV damage on Nitrile, but they do not change its basic weakness to sun and ozone.

- If every part of the rubber stays fully covered at all times, aging is slower.

- In real use, covers shift, coatings crack, or maintenance exposes sections — and those exposed zones start to harden and crack much like unprotected Nitrile.

Short-term outdoor storage with temporary covers is usually fine. For long-term outdoor service, however, we generally recommend:

- Neoprene for moderate oil and weather exposure.

- Viton for very harsh chemical and temperature conditions.

- Design changes that keep Nitrile inside protected housings while EPDM or Silicone handle the outer weather seal.

When clients bring this question to RK Rubber Enterprise Co., we review the actual exposure and suggest safer, more stable material combinations rather than relying only on covers or coatings.

Leave a Reply

Want to join the discussion?Feel free to contribute!